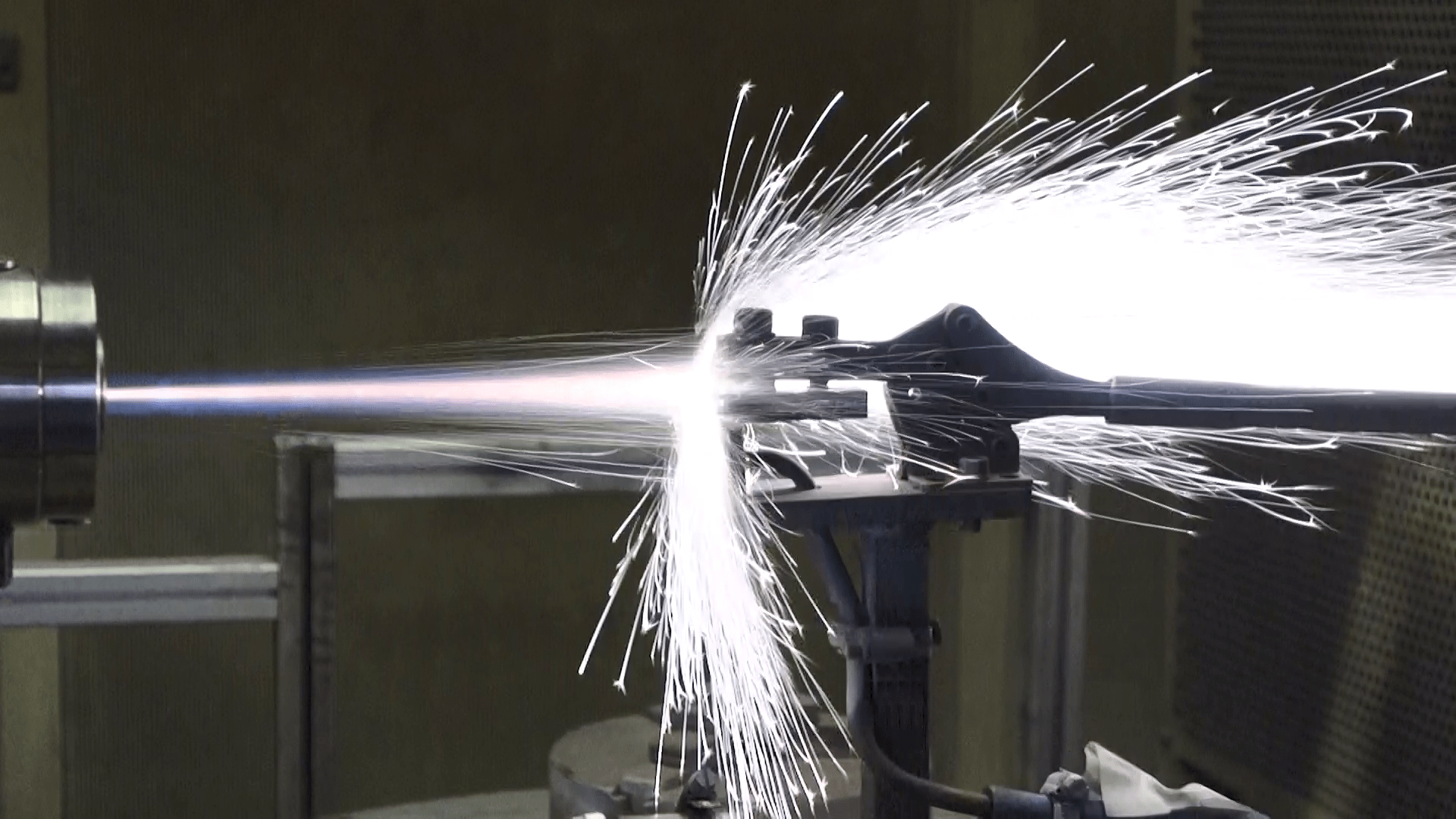

We introduce our new thermal spray system, a combination of two advanced innovative spray processes in a single highly-flexible production unit.

These advanced processes are integrated into Konbus+, our new thermal spray system.

We offer the most suitable technology for the best coating solution in each application.