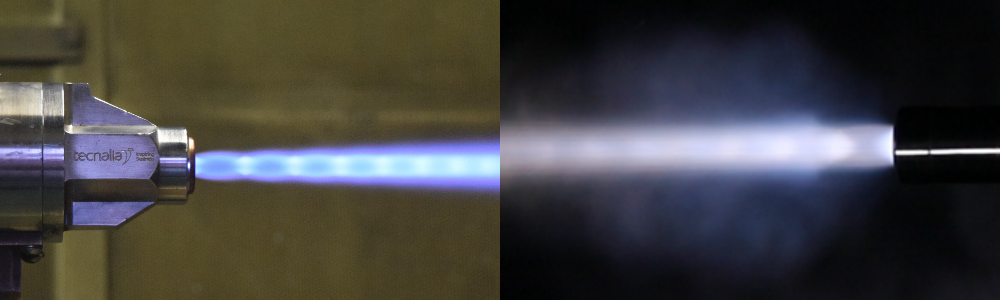

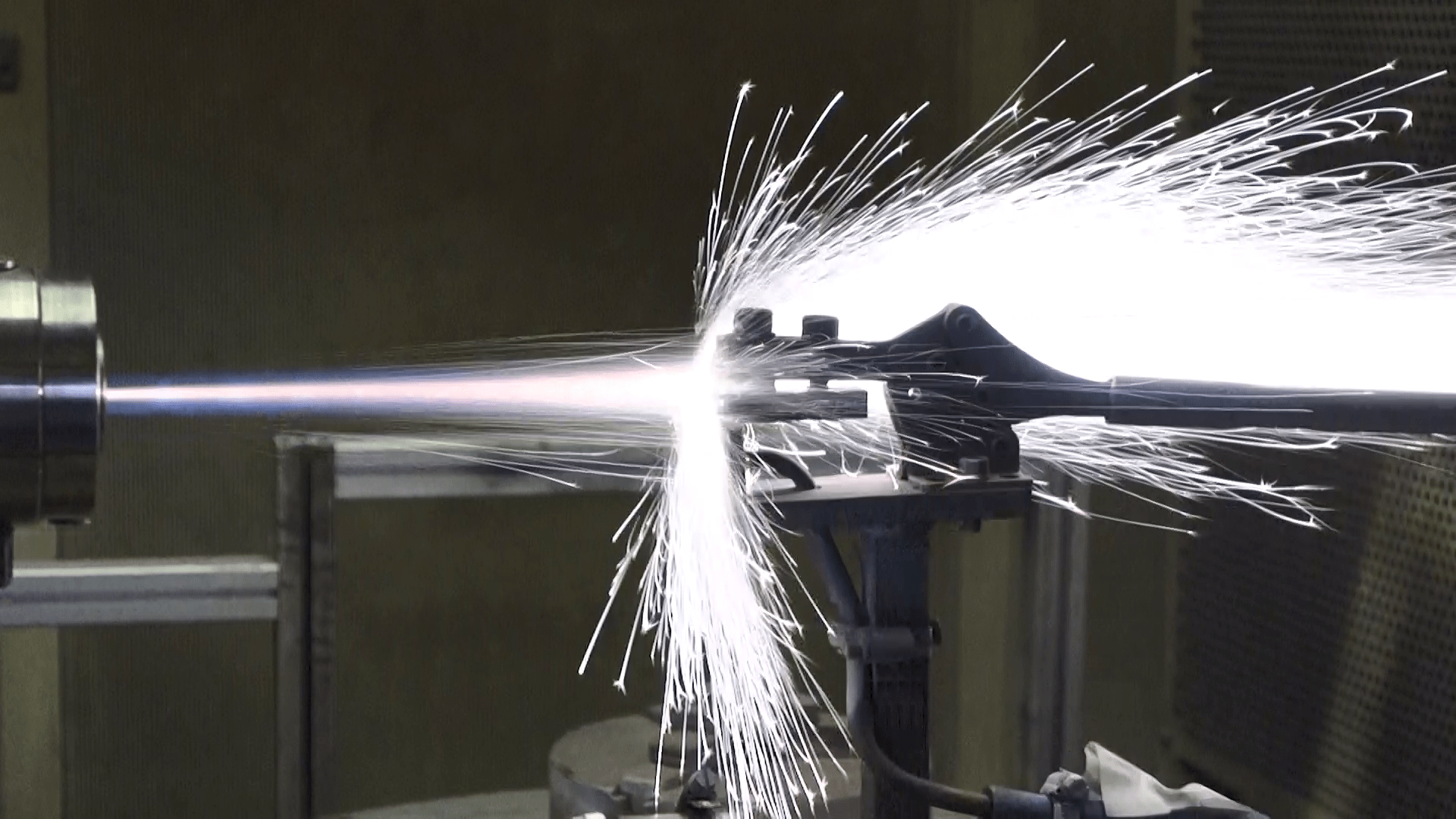

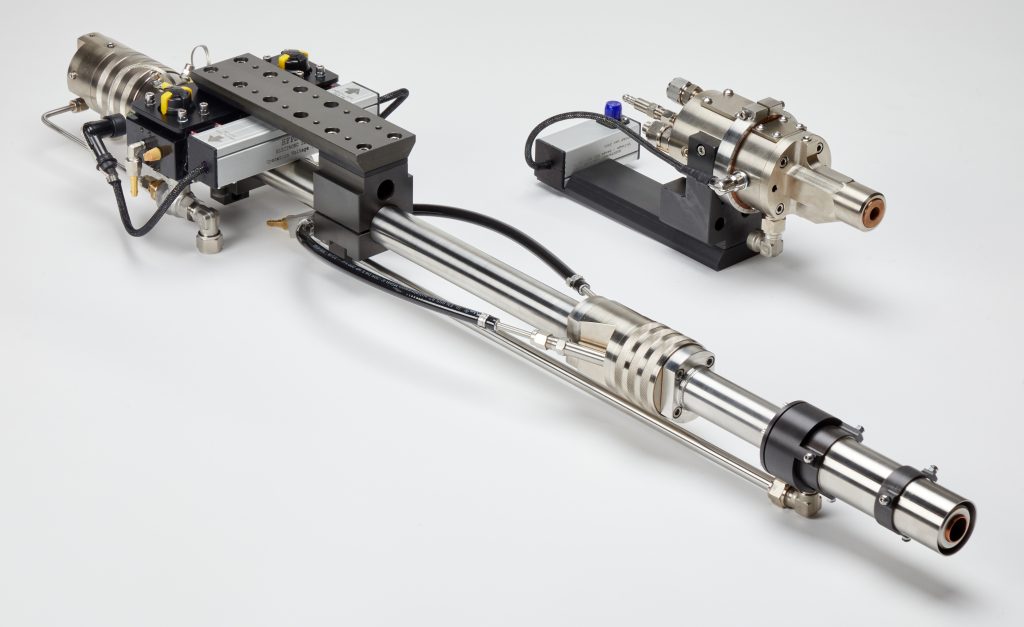

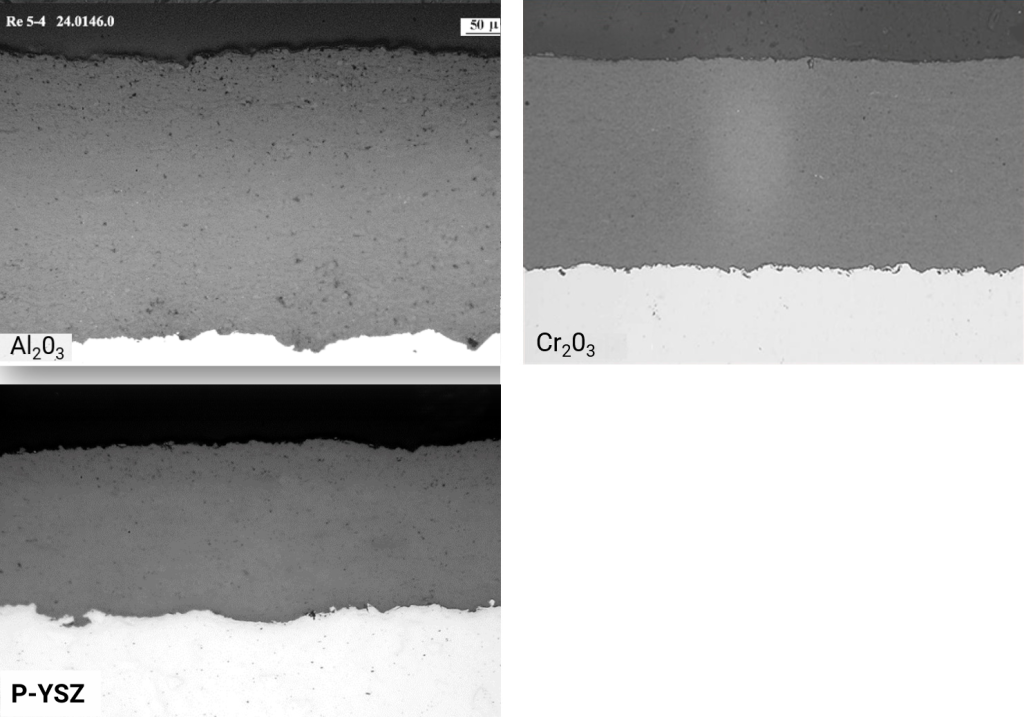

The HVOAF gun embodies the state-of-the-art in advanced supersonic spray systems based on oxygen/air fuel combustion. The system is designed to operate with natural gas (methane) as fuel and process powder feedstocks within a wide spectrum of thermal conditions and velocity regimes. From solid state deposition conditions to supersonic spraying of molten/semi-molten particles, the system is capable of producing customized coating solutions with common characteristics of high density, compactness, bond strength and fine surfaces, with values even outperforming their HVOF counterparts.

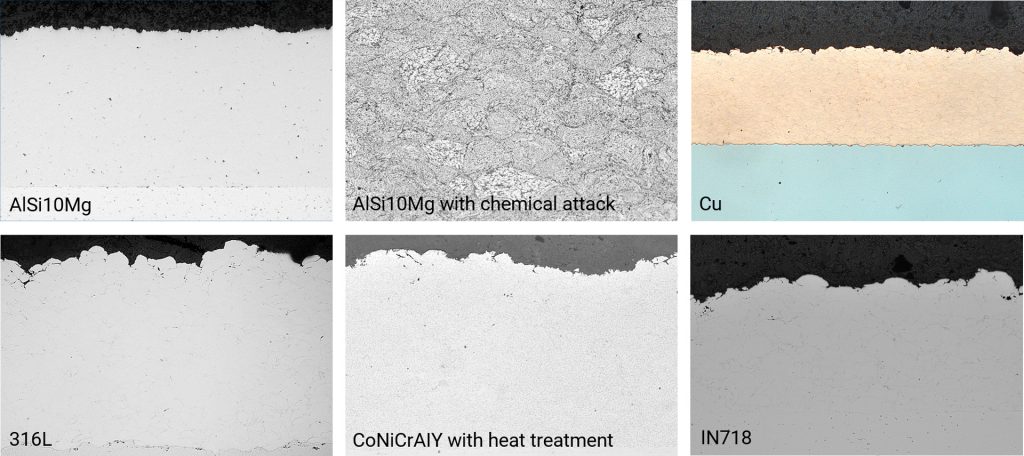

High quality coatings can be produced to provide wear resistance, corrosion protection, additive repair as well as other applications using light alloys, metals and cermet materials. The system is equipped with different barrel lengths to achieve the most optimal feedstock powder treatment for each case.