“Buckypaper is a material with great potential for the development of vehicles and infrastructure in the transport sector because it has a series of properties such as high electrical and thermal conductivity, greater tolerance to damage and resistance to fatigue”

Carbon Nanotubes for a Sustainable Economy

The transformation towards a sustainable economy requires materials that are more durable, lighter and improve electrical conductivity. The electrification of thermal vehicles is an ongoing process and a paradigm shift that requires both cars and aircraft adapted to the new economy and infrastructure to support these new transport systems.

In order to achieve these goals, Spain is one of the leading countries in Europe in terms of the development of buckypaper; a thin film made up exclusively of an aggregate of carbon nanotubes (CNT).

Buckypaper is a material with great potential for the development of vehicles and infrastructure in the transport sector because it has a series of properties such as high electrical and thermal conductivity, greater tolerance to damage and resistance to fatigue. Thanks to these features, this material is a potential substitute for metal structures, with the advantage of drastically reducing the strength-to-weight ratio.

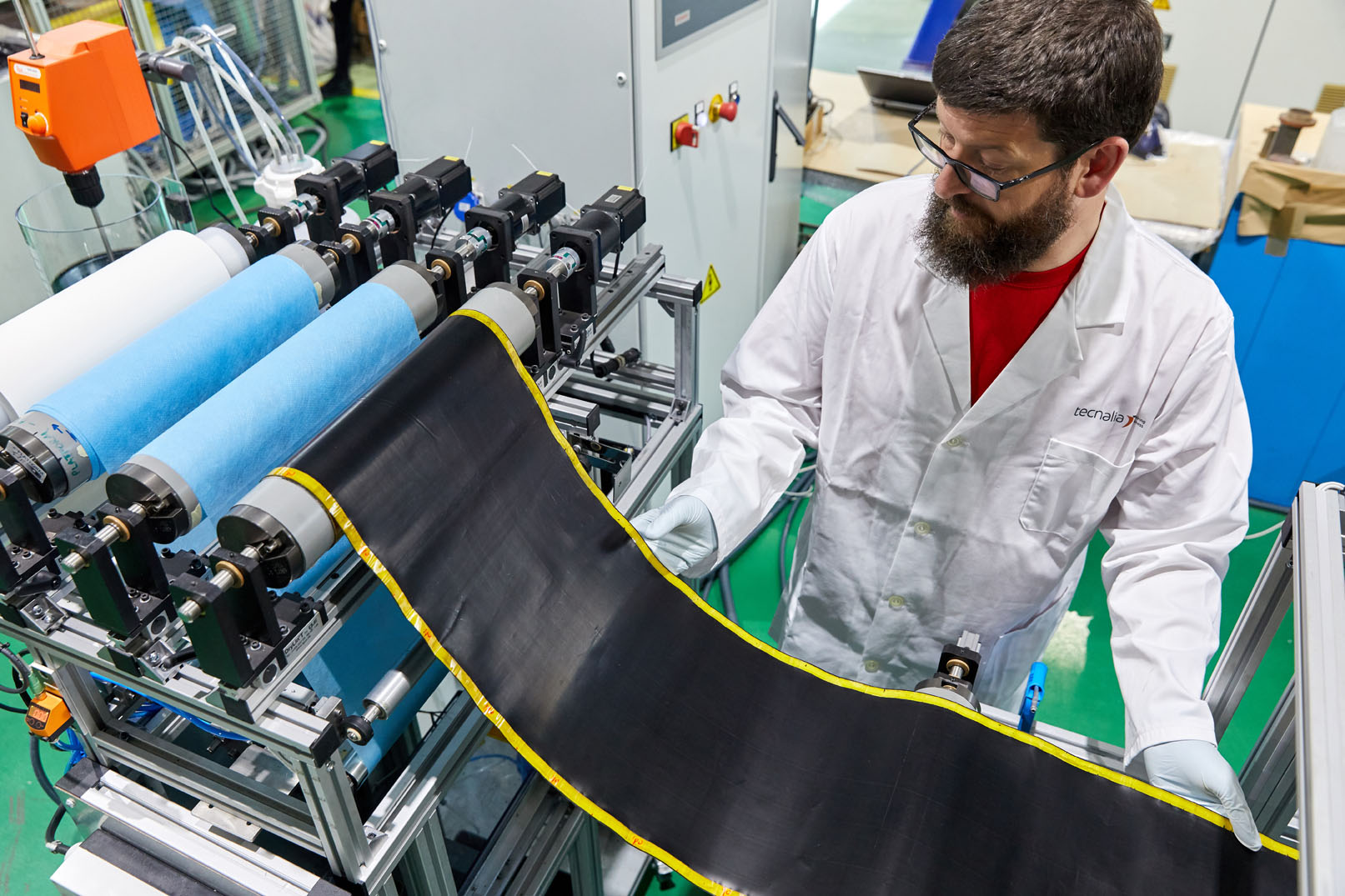

Pilot plant in collaboration with Sisteplant

TECNALIA, in collaboration with Sisteplant has developed a pilot plant that produces continuous sheets of CNT to be used in industrial processes, and is able to manufacture sheets of buckypaper that are up to 100 m, and up to 300 mm wide.

This pilot plant runs demonstrators that help solve some of the major challenges facing electric vehicles, such as reducing the weight of the vehicle itself, and the capacity of the batteries that power them.

Other applications where the great potential of buckypaper has already been proven include protection against lightning strikes, with a 25% decrease in the damaged area, for example. It can also be used with sensors that monitor the health of the infrastructure during its useful life.

TECNALIA’s research team is currently focusing mainly on expanding and automating its CNT manufacturing processes with the aim of reducing manufacturing costs, one of the main obstacles when implementing it on an industrial scale.