“TECNALIA develops technology that predicts degradation and improves the reliability of the most critical components”

TECNALIA develops innovative technology to improve the reliability of critical components in power electronic converters.

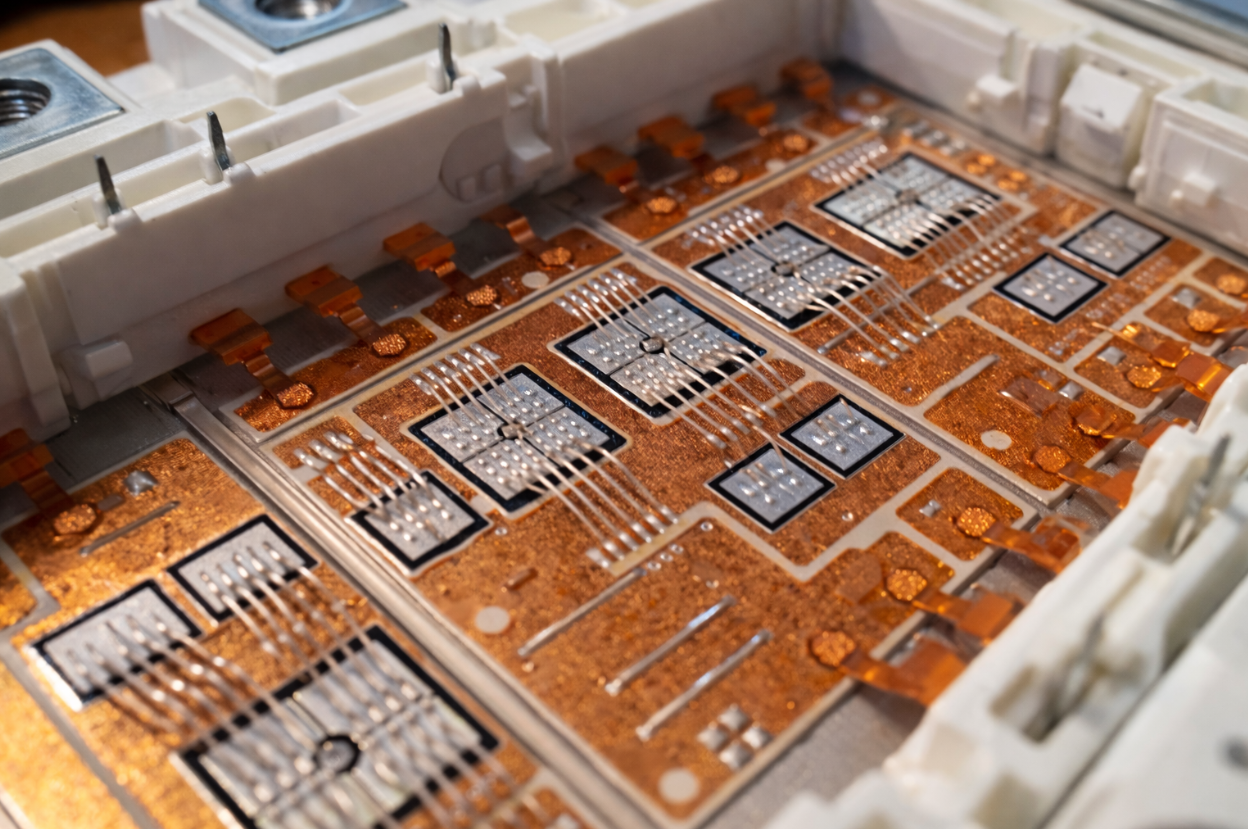

The CONFIA project focuses on improving the reliability of the two components with the highest failure rate in power electronic converters: silicon IGBT semiconductors and capacitors. The research addresses the thermo-mechanical degradation of IGBT encapsulation and aims to extend the lifetime of IGBTs by means of:

- Models to characterise operation and degradation processes

- Non-invasive measurement systems for monitoring electrical parameters

- Advanced diagnosis and prognosis algorithms based on AI techniques

- Control and modulation techniques to reduce thermal and harmonic stress

Expected results include non-intrusive circuits for estimating IGBT junction temperature, degradation state prediction algorithms and highly accelerated life testing (HALT) to optimise validation.

The challenge of reliability in power converters

More than 70% of the world’s electricity is processed by power electronic converters, which are used in applications such as renewables and electric mobility. Their reliability is critical, as power converters account for a significant percentage of failures in e.g. photovoltaic (37%) and wind (13%) systems.

This research will be a strategic opportunity for the Basque Country in terms of solutions that extend the useful life of its components or enable predictive failure detection, supported by its solid value chain in electrical and smart grids.

TECNALIA’s commitment to reliability in power electronics

TECNALIA is leading this proposal because of its expertise in the field of reliability of critical components in power electronic converters: it works mainly on the modelling and characterisation of the degradation process, as well as on the accurate estimation of this degradation by using AI techniques.

- CONFÍA is coordinated by TECNALIA, with the participation of five other actors of the Basque Network of Science, Technology and Innovation (RVCTI); the Polytechnic School of Mondragon Unibertsitatea (MU-EPS), Euskal Herriko Unibertsitatea (EHU), Ikerlan, Zigor R&D and BASQUENERGY Cluster.

- This project has been funded by the Department of Industry, Energy Transition and Sustainability of the Basque Government through the ELKARTEK programme.