"Specialised bonding processes for thermal management components under extreme conditions"

TECNALIA and AEROTECNIC have developed advanced bonding solutions for demanding thermal components

The research team at TECNALIA has achieved a new breakthrough in the development of specialised bonding processes for thermal management components under extreme conditions. These technologies are aimed at highly demanding sectors, such as nuclear fusion or aeronautical propulsion, where reliability and thermal performance are critical factors.

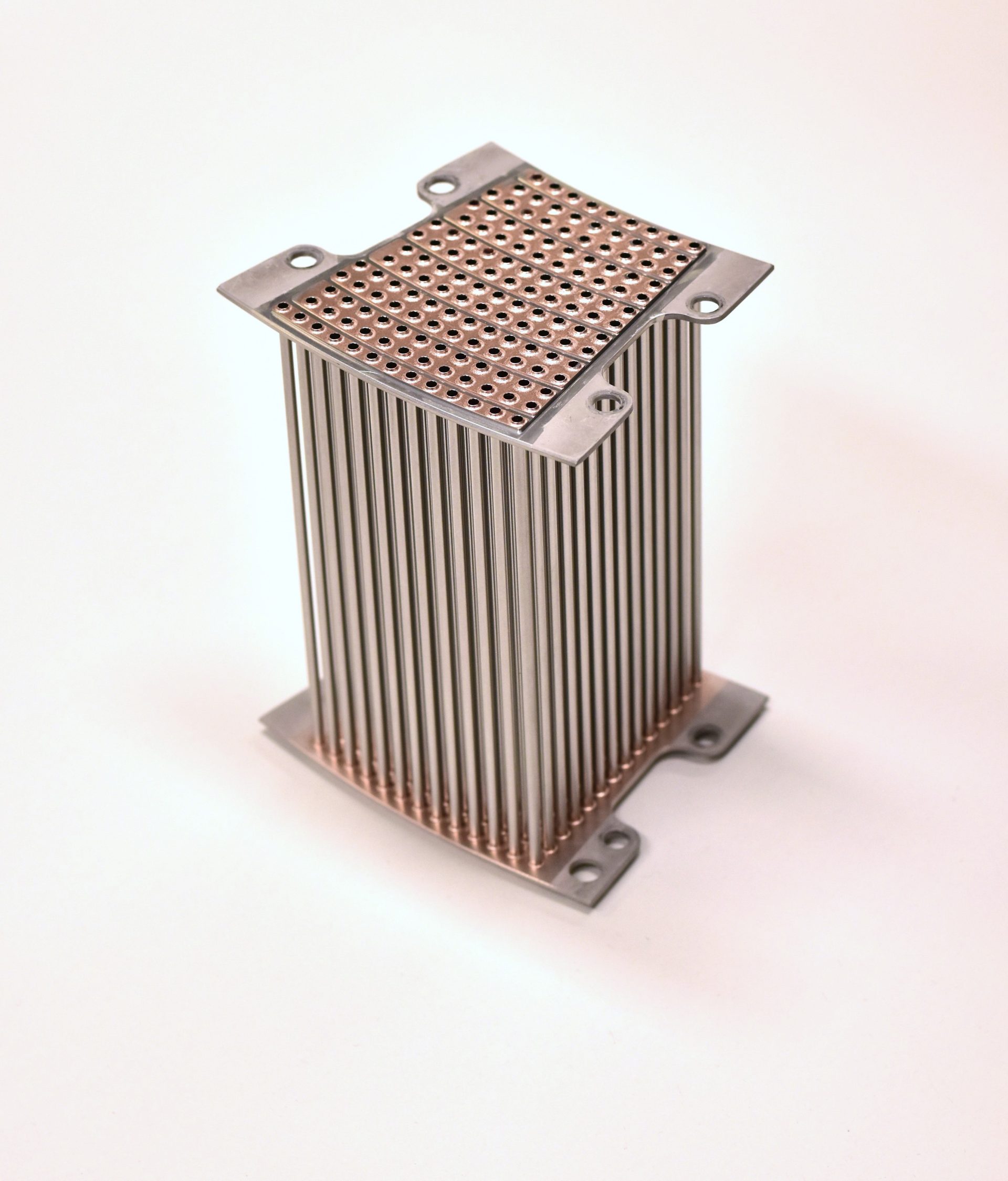

Heat exchanger

TECNALIA, in collaboration with Aerotecnic, has developed an innovative component that works as a heat exchanger. This device integrates capillary tubes through which hydrogen circulates at cryogenic temperatures, which is then heated by the flow of air through the structure.

- Preconditioned hydrogen is destined for combustion processes for the propulsion of new generation aircraft.

- The project has addressed the selection of hydrogen compatible materials, evaluation of different filler materials and validation of the mechanical strength and watertightness of the bonds.

- The bonding process consisting of brazing in a vacuum furnace which has been developed, ensures structural integrity, avoids deformations during manufacturing and enables components with high geometrical accuracy to be obtained, which is an essential aspect in critical applications such as aircraft engines.