“Innovation is once again at the forefront of the metal fabrication sector”

Automated welding redefines industrial productivity

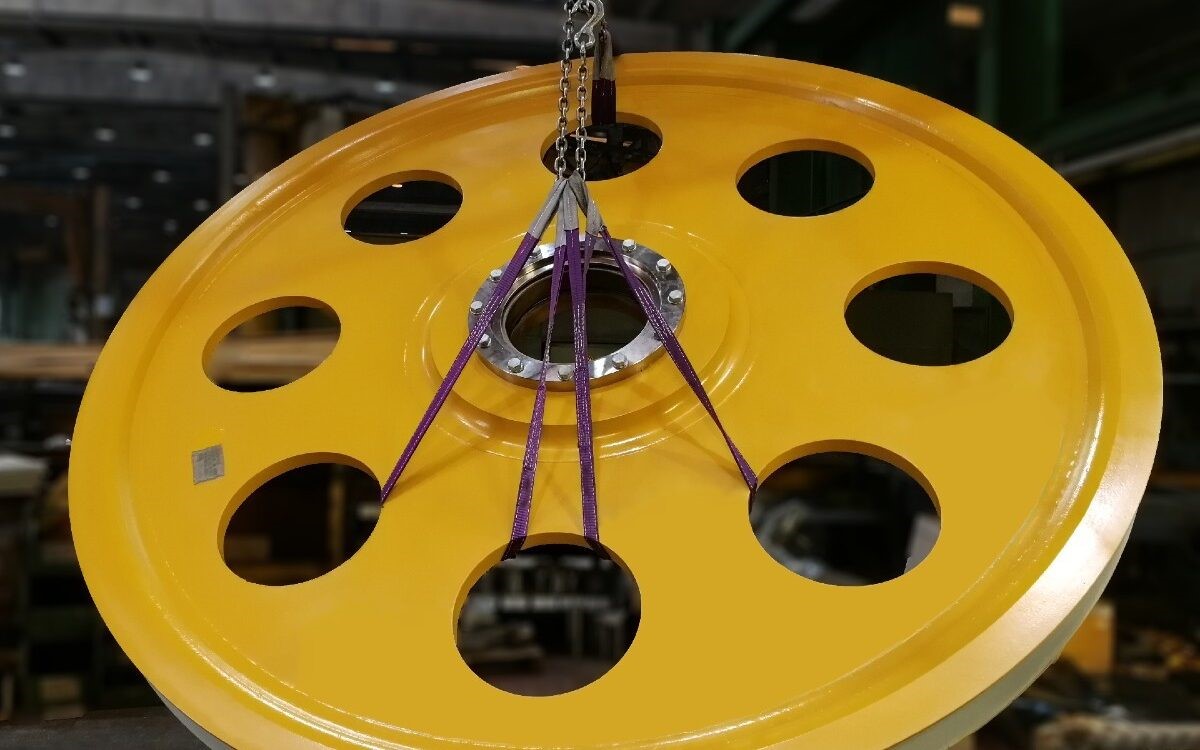

Innovation is once again at the forefront of the metal fabrication sector. GOSAN, an international benchmark for lifting solutions, has taken a decisive step into the future thanks to ARCUS project, which significantly increases the productivity of automated arc welding in its production cells.

The result is a true paradigm shift: faster, more productive and cost-effective processes, reinforcing the company’s position as a leader in technology applied to industry.

A revolution within the plant

The implementation of the innovative HW-GMAW (Hot Wire-Gas Metal Arc Welding) technology, validated and certified in GOSAN production centres, allows the incorporation of a second hot wire in each robotic arc welding cell. This increases productivity, eliminates downtime and ensures a level of repeatability and uniformity that would be impossible to achieve with manual processes.

This integration makes a difference in welding automation, achieving maximum productivity with continuous cycles, higher deposition volume and zero human fatigue.

- Quality assured: consistent seams, full traceability and fewer defects.

- Eefficiency and cost-effectiveness: optimisation of consumables and energy consumption thanks to automation.

With ARCUS, GOSAN is strengthening its commitment to innovation and operational excellence, consolidating a more efficient, reliable and competitive production model in the global market.