"Additive technologies do not replace conventional technologies: they transform them"

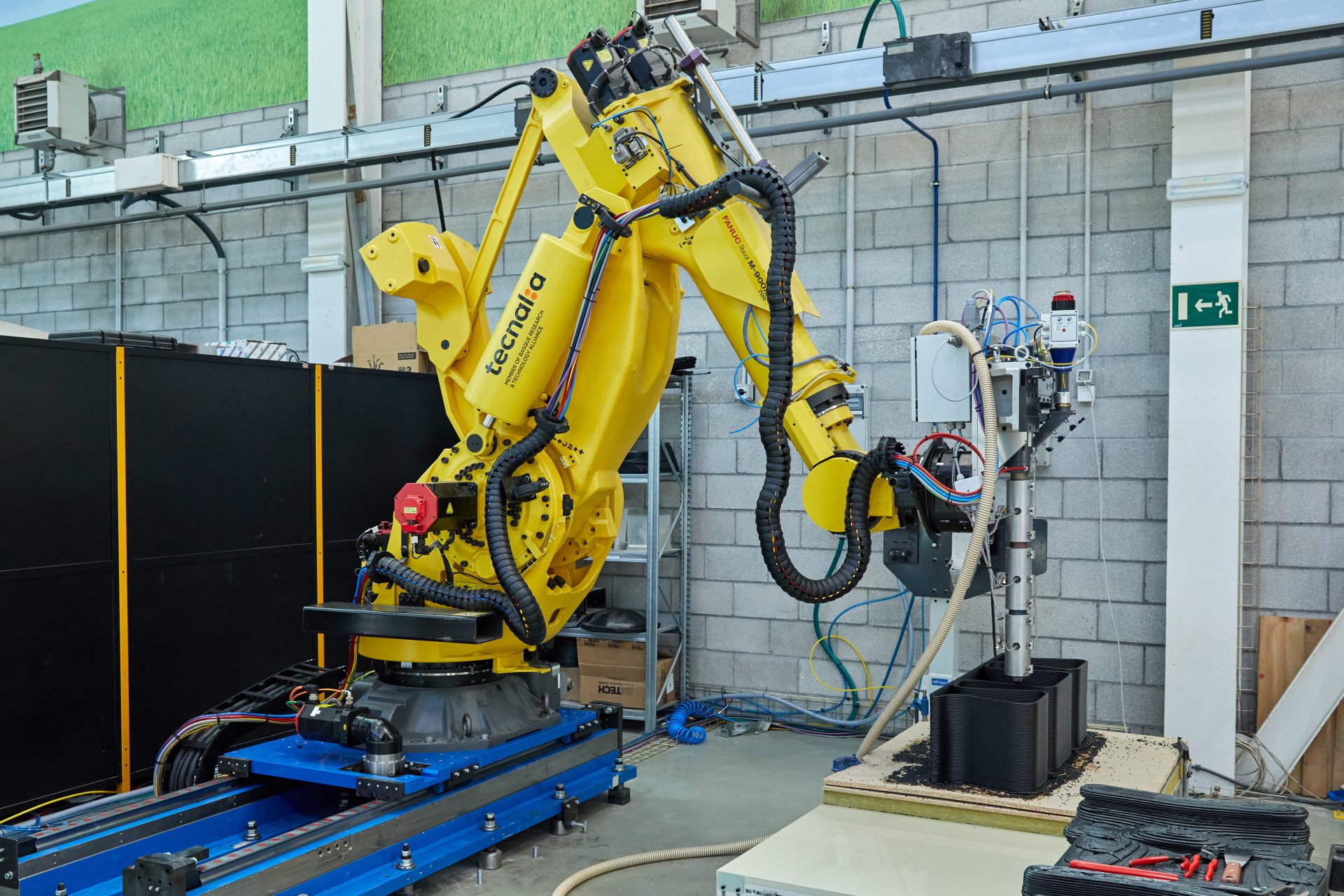

TECNALIA, in collaboration with Brayner, has developed a pioneering technology that combines the best of 3D printing with thermoplastic pellets and advanced machining processes.

The result is a hybrid solution capable of high precision manufacturing of moulds of up to three metres in length, significantly reducing production times, costs and waste generation.

This innovation opens up new opportunities for sectors like the automotive, construction, energy or shipping, which demand large-format moulds that are increasingly customised, complex and with a lower environmental impact. Furthermore, the technology enables recycled materials to be used, favouring a more circular and efficient industrial model.

This solution is not only viable, but also robust, stable and ready for its industrial deployment. Thanks to the MILLPELLETS project, we have set a milestone in the integration of additive technologies with chip removal processes, increasing productivity and sustainability in the manufacture of large moulds.

Additive technologies do not replace conventional technologies: they transform them.

We have brought together the best of both worlds to address new market demands with smarter and more sustainable processes.

TECNALIA continues to promote the development of a solid value chain in relation to this solution and we are looking for partners, industrial companies and integrators to participate in the transformation of the sector.