Functional printing enables the integration of electronic functionalities where it was previously not possible to do so effectively.

This is possible by means of printing techniques that allow localised deposition of functional materials on any substrate and geometry.

Where is the laboratory?

TECNALIA helps you to develop new products with greater added value through Functional Printing.

Functional printing is an emerging technology that promises to revolutionise the design and manufacturing of electronic devices. Thanks to new developments in printing techniques, from well-established screen printing to various digital jetting methods, it is now possible to deposit functional materials on flexible substrates and even directly onto the final part.

This enables the creation of circuits that adapt perfectly to the shapes and movements of the environment in which they are integrated, opening up a range of possibilities for the design of innovative and customised products.

Functional printing not only overcomes the challenges of size and rigidity, but also facilitates the production of electronic components such as sensors, heaters, antennas and lighting circuits. It can even replace conventional cabling, resulting in lighter and more space-efficient devices.

This technology is ushering in a new era in electronics, where flexibility and customised integration are key to meeting the demands of an ever-evolving market with increasingly high expectations.

TECNALIA’s value proposals allow the integration of electronic functionalities in an innovative way

TECNALIA works with other research teams to be the first to integrate electronic functionalities where it was not possible until now.

TECNALIA has specialised in the following solutions:

- Devices embedded in composite materials: We print directly onto dry fabric or use our own developed electrospun veils tointegrate functionalities into composite materials without compromising their mechanical properties.

- Direct printing on the final surface: Thanks to a unique 5-axis machine, we integrate the electronic functionalities by depositing the functional inks directly on 3D surfaces.

- Electronic additive manufacturing: We are able to do simultaneous fused filament fabrication (FFF) and functional inks, multiplying the possibilities of both technologies.

- RF applications and metasurfaces: We develop radio frequency applications enabling innovative sensors, wireless devices and electromagnetic metasurfaces.

How TECNALIA works with Functional Printing

TECNALIA has a multidisciplinary team that is highly specialised in differentiating technologies, and we want to work with you throughout the entire product development process, from the initial idea to the prototype:

- Definition of specifications

- Electronic design

- Selection and adaptation of materials

- Printing process development

- Printing, hybridisation and curing

- Functional characterisation

- Integration

- Testing and validation

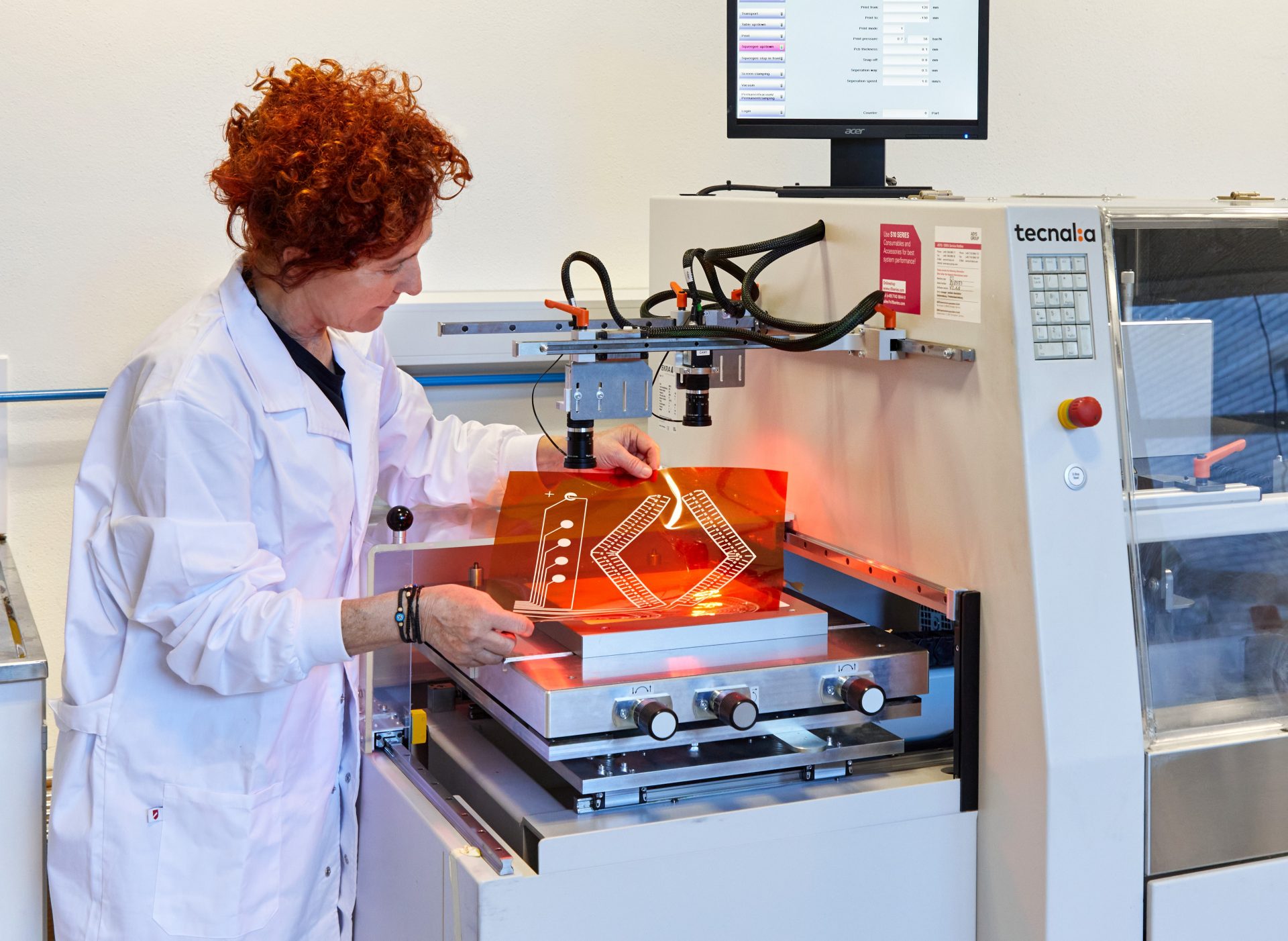

To do this, TECNALIA has a laboratory that allows greater flexibility, speed and reliability when executing functional printing processes. It has, among other things:

- Printing equipment on 2D surfaces: dispensing, inkjet, screen printing, etc.

- Unique equipment for printing and hybridisation on complex 3D parts: piezojet, aerosol jet, microdispensing, FFF, pick & place, etc.

- Ink curing equipment: UV curing, ovens, etc.

- Ink characterisation equipment

- Equipment for functional characterisation

Tell us about your challenge and we will work closely with you to develop solutions to make you more competitive.

Who we can help

- Product development companies interested in incorporating electronic functionalities and whose challenges cannot be faced by conventional electronics.