“TECNALIA strengthens hydrogen laboratory with H2TESTLAB, a unique materials testing infrastructure”

TECNALIA has strengthened its hydrogen laboratory with H2TESTLAB, a unique infrastructure for testing materials and components aimed at the generation, distribution and use of renewable hydrogen

This extension is part of TECNALIA’s goal to accelerate innovation and improve industrial competitiveness in the hydrogen value chain, by constantly including new experimental capabilities and advanced infrastructure that allow it to offer a better service to companies and the industrial ecosystem as a whole.

With a focus on the development and scaling-up of next-generation electrolysers, the compatibility and durability of materials, storage, safety and industrial uses of hydrogen, H2TESTLAB joins the rest of the testing, validation and technological demonstration capabilities available in the laboratory, as well as the rest of the laboratories across TECNALIA’s sites.

Thanks to this new infrastructure, the laboratory has consolidated its position as a benchmark for the development, testing and demonstration of renewable hydrogen technologies, incorporating new equipment, test benches and advanced systems aimed at the analysis of materials, components and critical systems.

H2TESTLAB – unique equipment

The project has enabled the creation of unique renewable hydrogen infrastructure and equipment at TECNALIA’s facilities in Donostia-San Sebastian, by means of the design, assembly and commissioning of new testing systems, including the following:

- AEM (Anion Exchange Membrane) electrolyser test bench, to assess advanced renewable hydrogen production solutions.

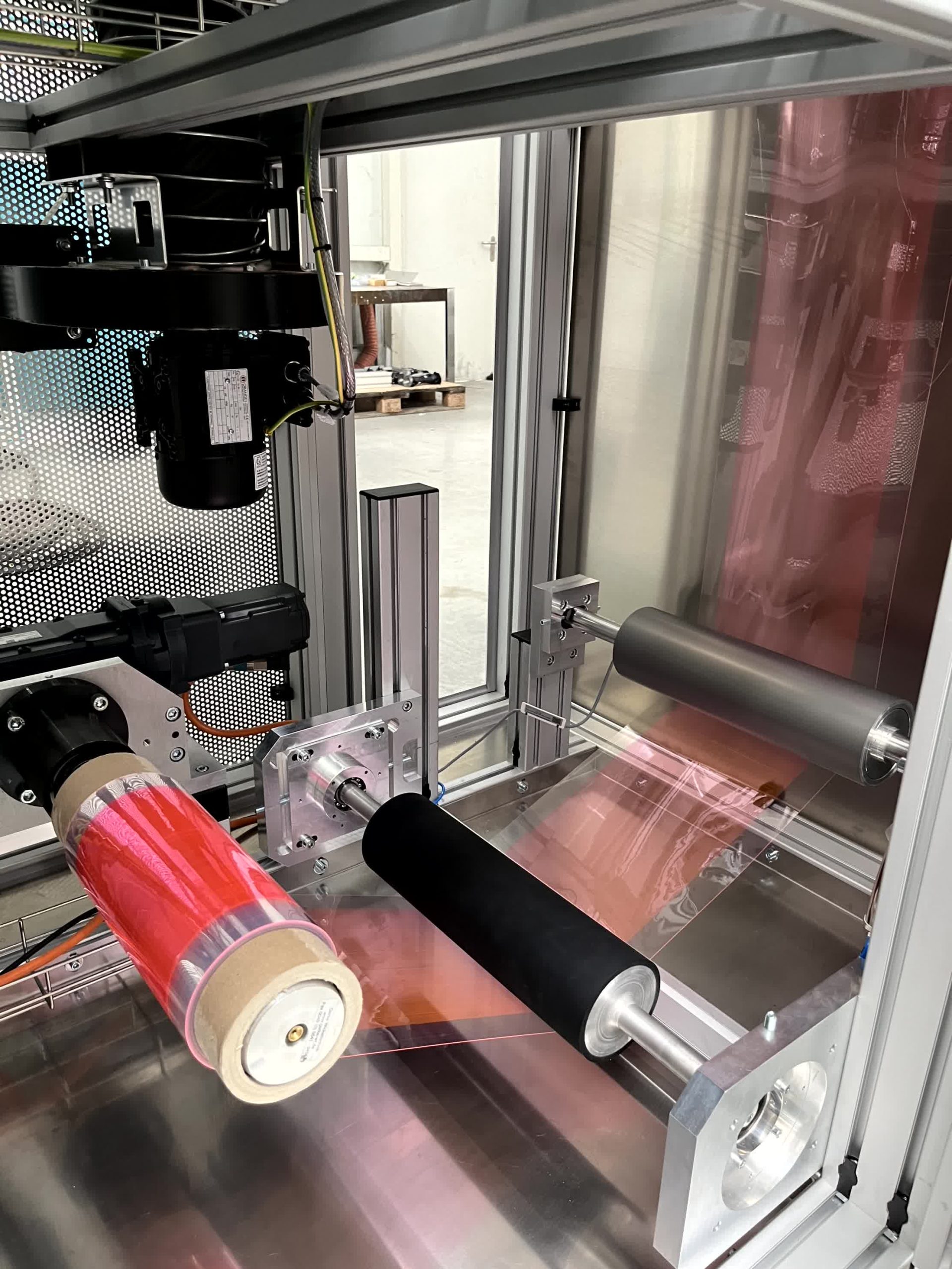

- Electrolysis membranes test bench, focused on performance analysis and material degradation.

- Embrittlement and material compatibility test bench, key to assessing the safety, reliability and durability of components exposed to hydrogen.

- Hydrogen sensor test bench, aimed at validating critical detection and monitoring technology.

- General laboratory infrastructure, integrating control electronics, safety and ventilation systems specific to hydrogen facilities.

PERTE ERHA

TECNALIA has led the H2TESTLAB project through Programme 1 of the PERTE ERHA call for aid by IDAE (Spanish Institute for Diversification and Saving of Energy), aimed at promoting capacities, technological advances and the implementation of test and/or manufacturing lines in the renewable hydrogen industrial value chain.

This milestone is part of the support programmes for the renewable hydrogen value chain, geared towards innovation, knowledge generation, development of technological capabilities and demonstrators, within the Recovery, Transformation and Resilience Plan (PRTR).