"We reduce raw material consumption by producing moulds in thermoplastic material via additive manufacturing"

Raw material consumption has become a strategic priority to maintain competitiveness in industries such as aeronautics and wind power

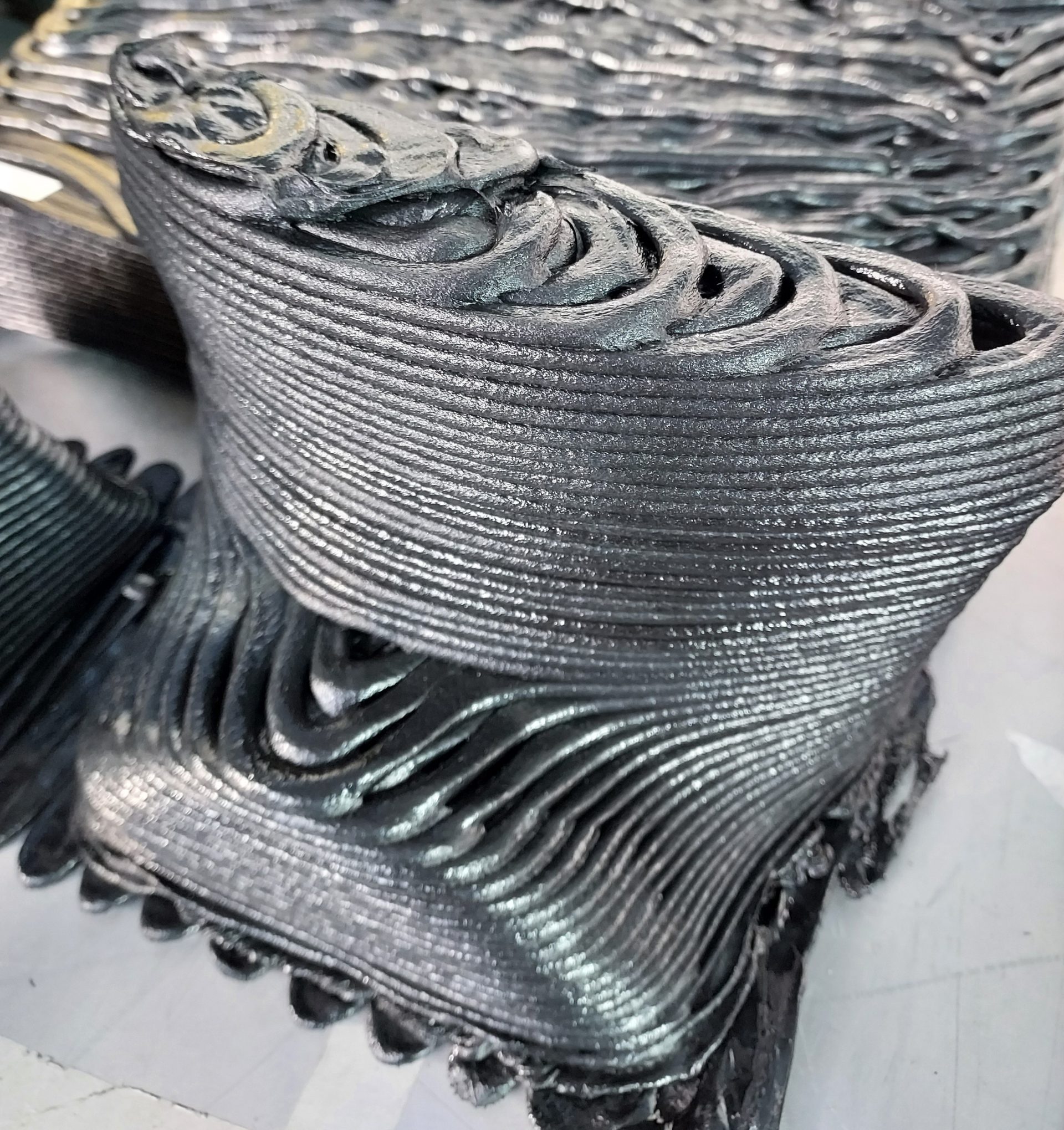

In the MOLDAM initiative, co-funded by EIT Manufacturing, we have developed a solution to produce mould preforms in thermoplastic material with a robot-integrated extruder system, combining an existing additive manufacturing technology. This technology is capable of printing moulds of complex shapes, guaranteeing their operation in specific real conditions, which have been previously simulated using the characteristics of the material tested at the operating temperature.

The MOLDAM additive manufacturing cell comprises both the hardware and software required for process automation. Furthermore, the digital twin of the robotic cell has been developed, which monitors the entire production process by acquiring data from integrated sensors.

More about the Moldam project

Moldam is made up of five organisations; Aernnova-ICSA and Suzlon Blades are the validators of the moulds designed and manufactured according to their requirements.

Preliminary results obtained reflect good performance of the mould preforms under the operating conditions. The design has revealed less consumption of raw materials in the manufacture of the moulds. Furthermore, a reduction in production times is achieved by generating less material waste compared to the previous mould production technique.