“Life cycle analyses confirm a significant improvement in the environment compared to current landfill practices”

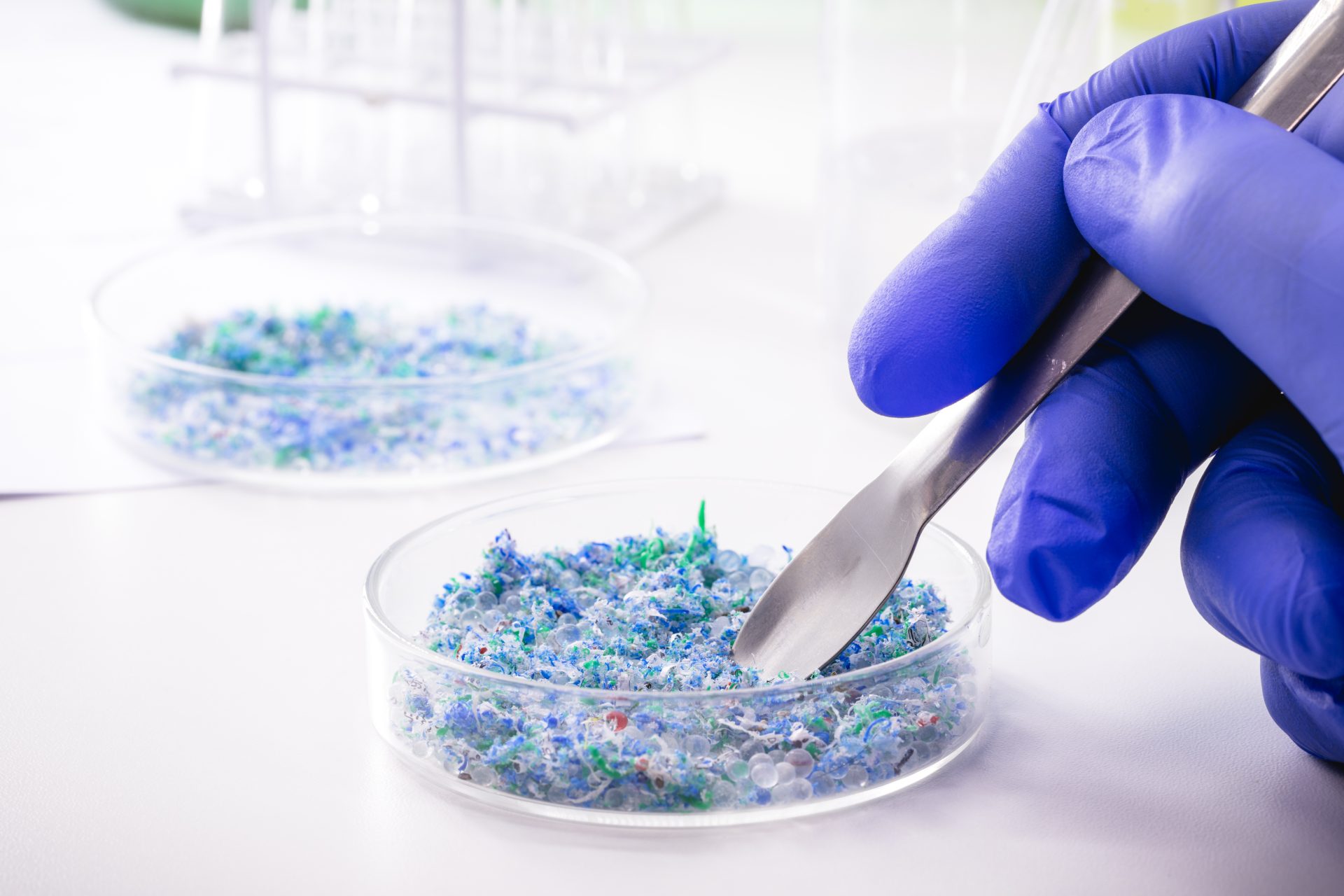

TECNALIA works with GAIKER, UPV/EHU and POLYMAT to develop chemical recycling technologies to create high value products from complex plastic waste

TECNALIA develops and optimises chemical recycling processes, in the NEOPLAST 2 initiative, to convert different plastic waste into high quality resources, capable of meeting the specifications required by the most demanding secondary raw material markets.

This makes it possible to obtain high-value products from plastic waste that is not currently recycled and ends up in landfill sites. Consequently, NEOPLAST 2 is a major step towards closing the life cycle of complex plastics.

Results obtained

Among the most outstanding advances is the combination of processes such as solvolysis and the purification of products to obtain monomers and precursors which are useful in manufacturing new polyesters and polyurethanes.

- Processes for the selective dissolution of textile waste mixtures (natural and synthetic) have also been explored.

- Technologies based on pyrolysis and separation have been developed for producing hydrocarbons with applications in polyolefins and adsorbent materials.

- The project has also implemented a two-stage gasification process to obtain hydrogen gas, and has explored new routes such as biorecycling using enzymes and microorganisms.

- In addition, studies have been carried out on plastic waste, such as thermosetting composites, which are not widely recycled.

Significant environmental improvement

Life cycle analyses have confirmed an improvement in the environment compared to current landfill practices, and have found a reduction in negative impacts on both human health and the environment.

The initiative, which is supported by the Basque Government through the ELKARTEK programme, has been led by GAIKER with the participation of TECNALIA, the Department of Chemical Engineering and the Department of Chemical Engineering and the Environment of the UPV/EHU and POLYMAT, respectively.