Laboratory specialising in the preparation and microstructural characterisation of materials, exploring their relationship with mechanical, chemical and physical properties and their thermo-mechanical history.

Our team of experts has extensive experience in the field of materials analysis (metals, polymers, composites, ceramics, etc.), joints and coatings.

Main tests and equipment in the metallography laboratory

The main tests and analyses we perform are:

- Macrographic examination (welded joints, fibres, etc.).

- Micrographic analyses:

- Optical microscopy analysis of all types of materials (microstructure, grain size, determination of non-metallic inclusions, measurement of coating thickness, fibre/resin distribution, micro-sections of electronic components, etc.).

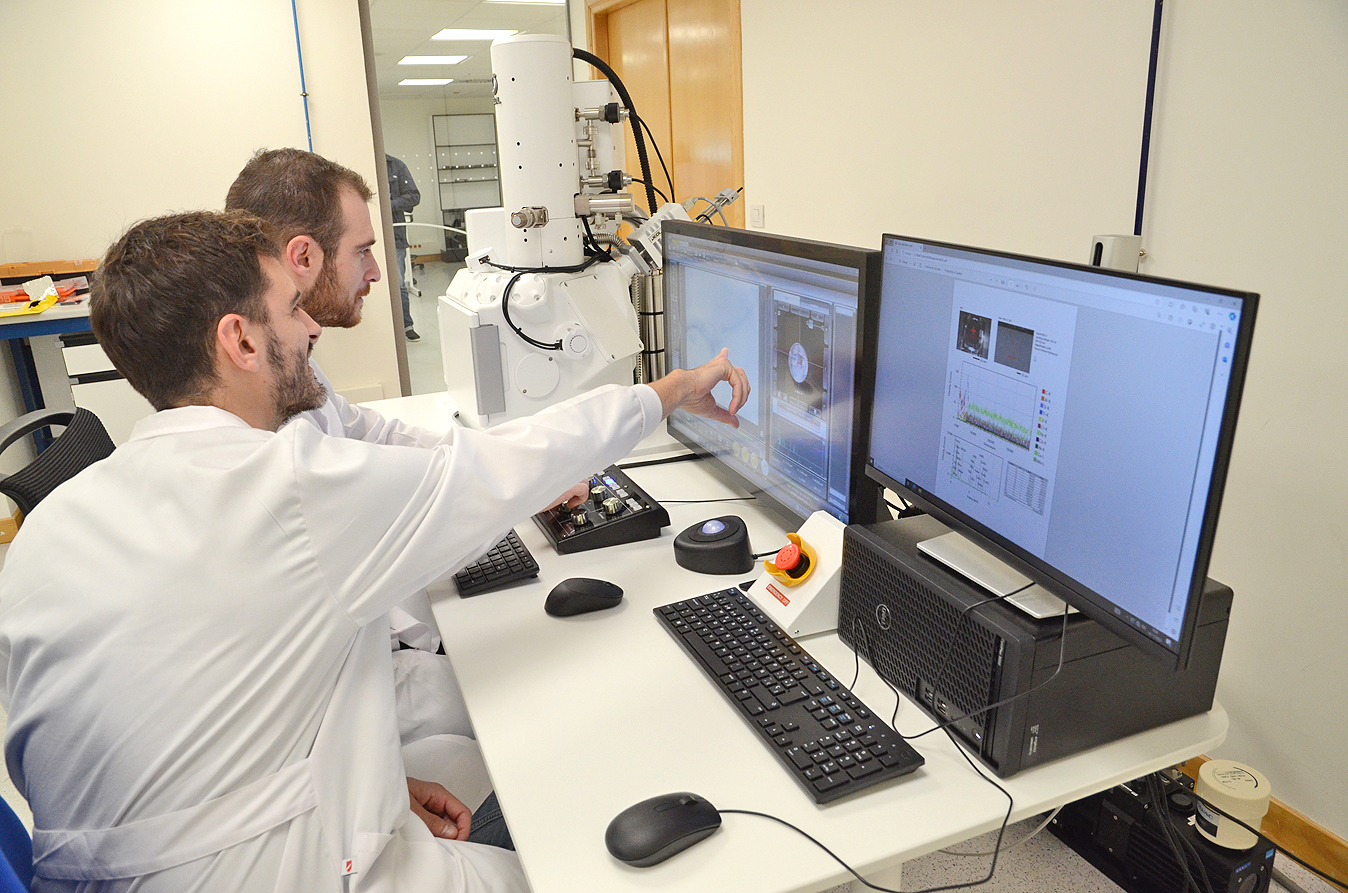

- Analysis using scanning electron microscopy (SEM) such as fractographic analysis, microstructure, defectology and identification of constituent elements using the Energy Dispersive X-ray Spectroscopy (EDX) technique.

- Quantification of phases/particles/pores through image analysis.

- Vickers microhardness testing and determination of the depth of surface heat treatments.

- Analysis using X-ray diffraction (XRD): Identification and quantification of phases, textures, layer measurement, etc.

- Corrosion testing:

- Intergranular corrosion testing

- Pitting corrosion testing

The laboratory has the following equipment:

- Automatic and semi-automatic optical microscopes with built-in digital camera with up to 1000x magnification.

- Thermoionic scanning electron microscopes (SEM) and field emission electron microscopes (FE-SEM) with EDX microanalysers.

- Software for digital image processing (measurements, grain size, micro-inclusions, phases and casting analysis).

- Automatic Vickers microhardness testing equipment.

- X-ray diffractometer (XRD).

- Stereoscopic magnifying glass with up to 200x magnification.

- Portable device for field metallography.

- Metallographic replication.

Aimed at:

- Renewable energies

- Manufacturers of metal components

- Metal transformation sector

- Oil & gas sector

- Construction sector

- Manufacturers of components for the aeronautical, railway and automotive sectors

- Design and maintenance engineering firms

- Infrastructure

Certifications and Accreditations

Laboratory certified in ISO 9001 and ISO 17025 (ENAC certification No. 4/LE063)

ENAC ILAC accreditation for the construction sector in compliance with ISO 17025, under file No. 4/LE024

ENAC ILAC accreditation for acoustics in compliance with ISO 17025, under file No. 4/LE456. Laboratory with certified management system in accordance with standard UNE-EN 9100:2010.

AIRBUS authorised Laboratory for surface treatments

Nadcap accreditation for chemical processes

Nadcap accreditation for material testing