Infrastructure for separating, treating and recovering different types of waste, and chemical process simulation programs.

This platform is geared towards studying technologies in laboratories and subsequently validating them in pilot plants, thereby making it possible to undertake a technical and economic assessment of their industrial scale in order to minimise investment risks.

Description

The platform has the following equipment:

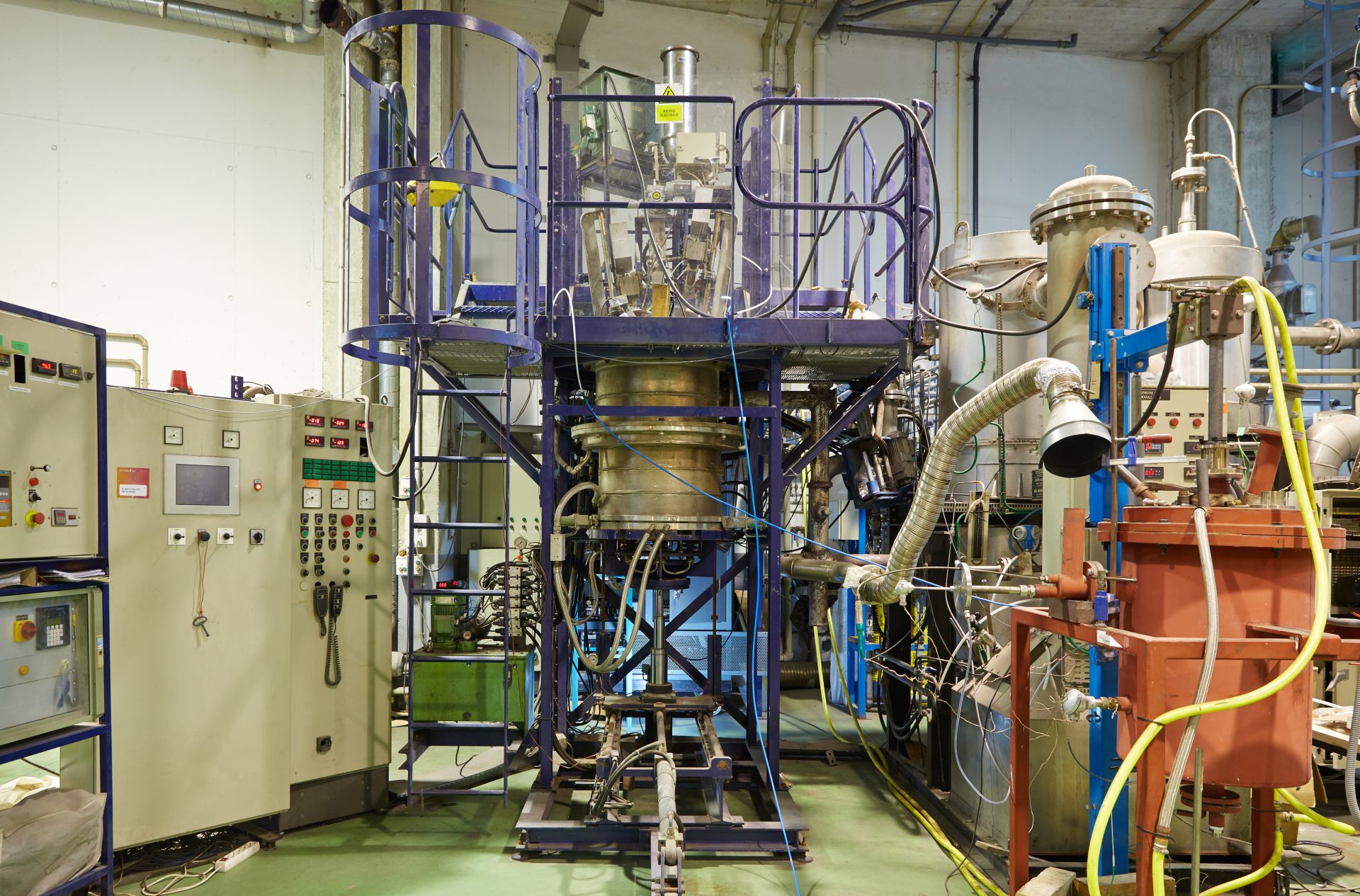

- Plasma pilot plant: recovery of metals using pyrometallurgical processes and vitrification of waste. It includes a feeder, a reactor equipped with a plasma torch and a gas treatment system.

- Low / medium temperature furnaces and possibility of controlled atmosphere (muffle furnaces, tube furnaces and rotary furnaces): these make it possible to recover the inorganic fraction (metals) in waste materials after the elimination of the minority organic fraction.

- Ion / hydrometallurgical processing plants: with capacity from 0.5 l to 80 l and electrical and thermal fluid heating. These plants focus on recovering recoverable metals through extraction using aqueous media or ionic liquids.

- Facilities for the synthesis of ionic liquids (on a scale of 10 l): these include characterisation techniques, reactors and pilot cells for electrodeposition. They focus on design, synthesis, physical-chemical and electrochemical characterisation, and on the properties and performance of “ionic liquids” (ILs) and “deep eutectic solvents” (DESs) for different applications.

- Equipment for pre-treating samples: mills, sieves and a briquette-making machine

- Equipment for characterising waste materials: ICP-MS, ICP-OES, AA spectroscopy, X-ray fluorescence, among others.

Aimed at:

- Companies in any industrial sector interested in managing their waste.

- Eco-industry