"Thanks to WAAM technology, we can manufacture more sustainable and smarter metal parts"

We rely on WAAM Wire Arc Additive Manufacturing technology to provide industrial companies with a solution to make metal parts more sustainable and smarter

WAAM technology enables the production of more sustainable and smarter metal parts, while optimising the lengthy processes of the value chain with the possibility of producing shorter series with great design freedom and improved mechanical performance.

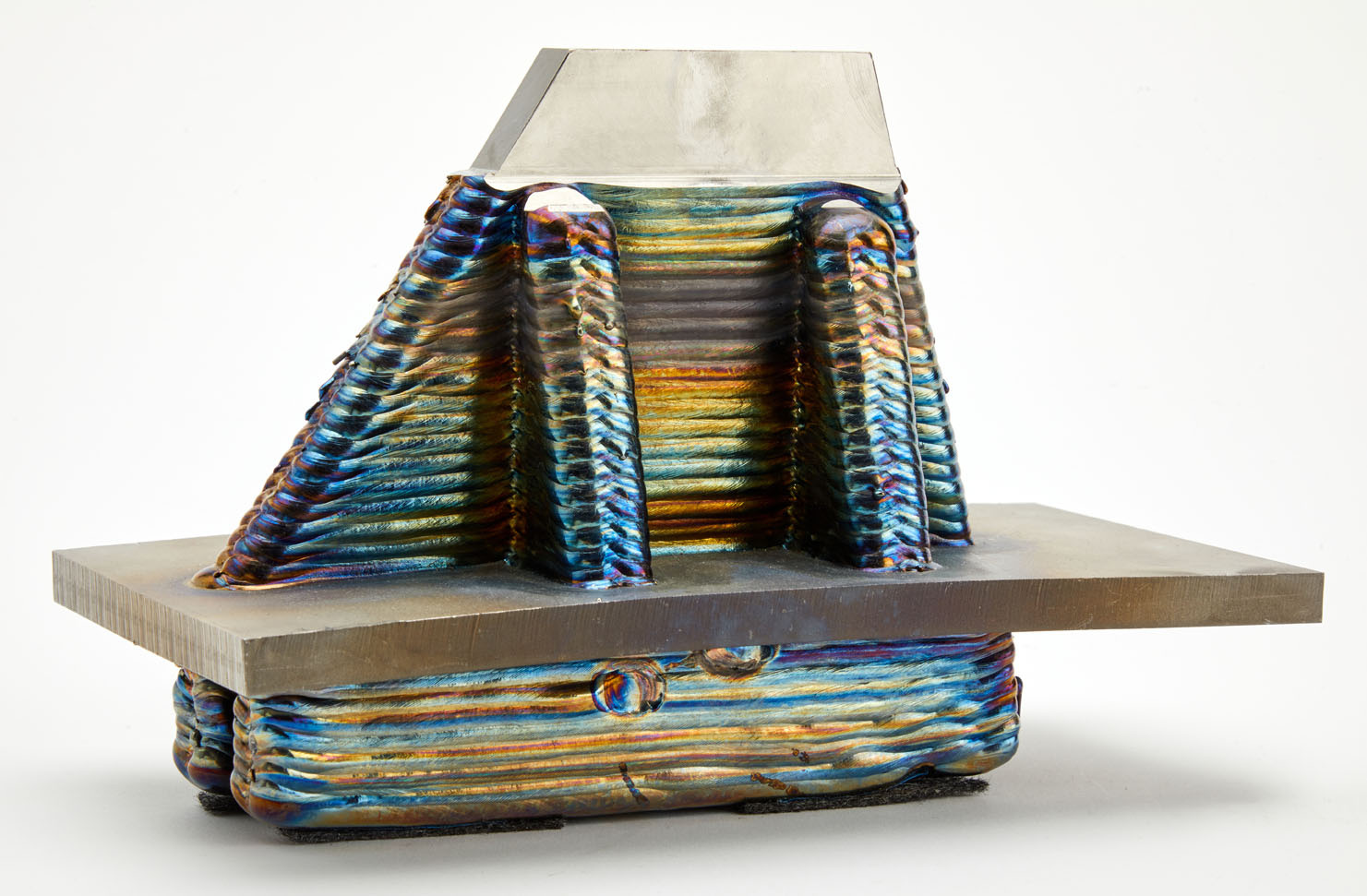

This technology consists of an additive manufacturing process, which combines metallic material in the form of wire, with arc welding techniques to melt it, and generate the layers that will form the geometry of the final part. To address these production challenges, we re working with Addilan on the Multiwaam project to analyse thefeasibility of manufacturing multi-material parts using this technology.

The manufacture of multi-material parts using this technology is an aspect that is generating increased interest in industry, when it comes to obtaining parts with better mechanical performance and cost savings. For this reason, we are developing an alternative, more sustainable, versatile and smarter metal additive manufacturing technology for the transformation and generation of a more efficient industry through process development and optimisation.

Manufacture of multi-material parts

WAAM technology has an increasing number of applications in different industrial sectors: it offers the capacity to manufacture large parts with high productivity, while taking advantage of the inherent advantages of additive manufacturing, such as maximum material utilisation, the possibility of obtaining more complex geometries or customisation.

Among the new applications, one of the most innovative is the manufacture of multi-material parts. These parts, made up of parts of more than one material, cannot generally be manufactured by conventional methods. Use of this technology is a great improvement and a solution to various applications; these can be found in sectors such as oil & gas, aeronautics and automotive.