The aim is to give recycled materials a new life with value-added applications and to provide effective tools for tracing and separating hazardous and valuable materials.

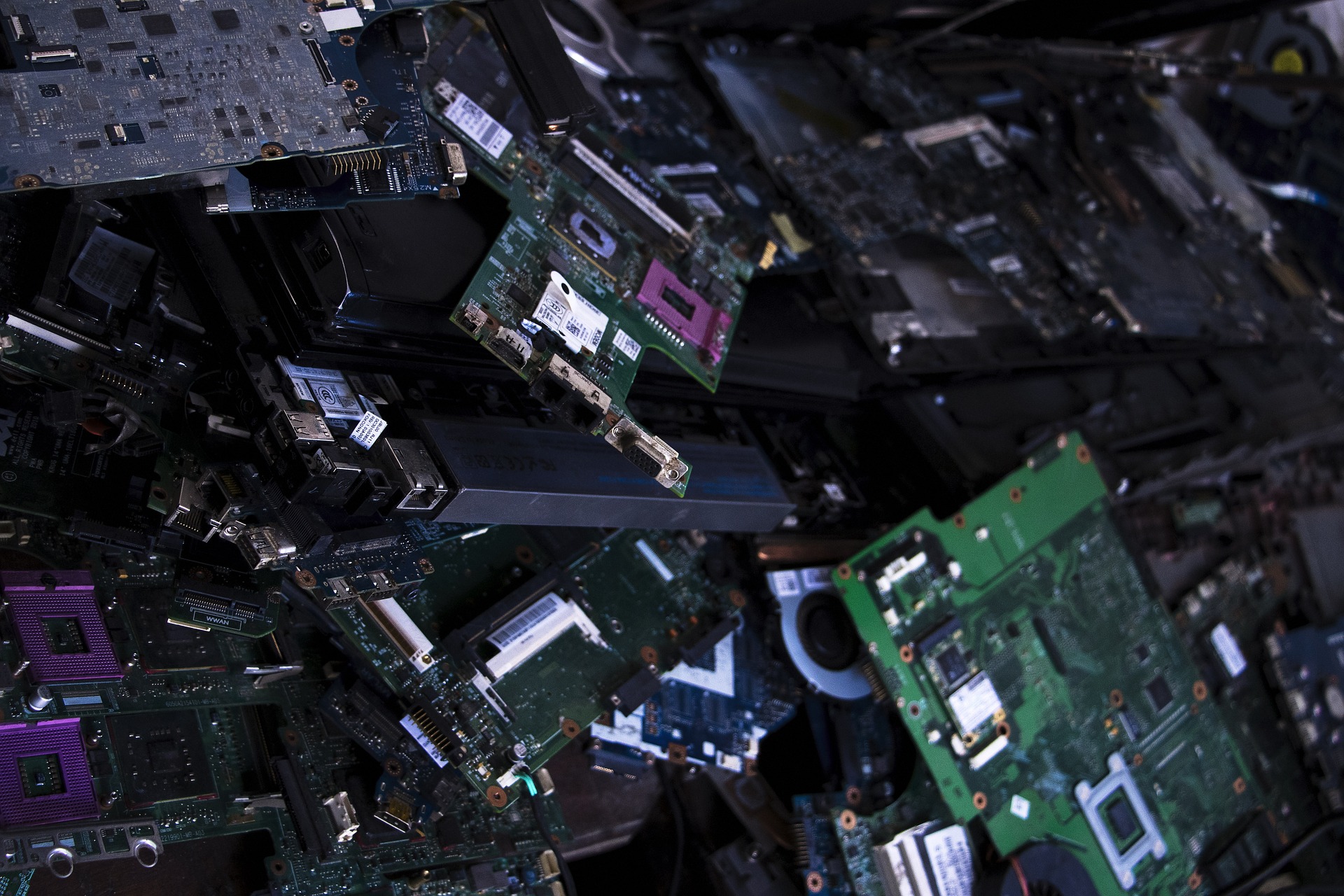

Waste Electrical and Electronic Equipment (WEEE) is a complex waste source. It contains components made of different materials (valuable resources), which can be found in this waste in significant proportions: aluminium, paper, glass, ferrous metals, non-ferrous metals, cardboard and plastics, among others.

The European WEEE Directive requires that secondary raw materials that can be found in the waste must be recycled and recovered. In the case of WEEE recycling, a large amount of plastics cannot be recovered during the recycling process due to the presence of hazardous compounds such as brominated flame retardants.

In 1980, the weight of plastics in electrical and electronic equipment was estimated to be 15%. 20 years later, this had risen to 20%.

The CLOSEWEE initiative has integrated three interlinked areas of research and innovation for the improved, resource-efficient recycling of polymeric materials, and critical raw materials from electrical and electronic equipment (EEE):

- Dismantling EEE efficiently and effectively is key for high quality material fractions, material separation, and also for reusing components and parts. An information system has been developed for companies specialising in dismantling to reduce the destruction of reusable parts and components and to allow for a more thorough and economically viable level of dismantling.

- Development of innovative, resource-efficient solutions to complete the loop of post-consumer high-grade plastics from WEEE, for new EEE through the advanced recovery of valuable plastic streams that do not yet have a recycling system, and the subsequent replacement of halogenated flame retardants with halogen-free flame retardants in new EEE (where the work of TECNALIA, specifically the SUSPOL building technologies group) has been focused.

- Improved recycling of lithium-ion batteries by increasing cobalt recovery rates and conducting research into a recovery technology for the critical raw material graphite, a constituent of lithium-ion batteries. These technological innovations in the various stages of the EEE recycling value chain are complemented by research on the reuse of recovered polymer fractions in new EEE, the definition of product design measures aimed at an optimised recycling ecosystem, and the incorporation of product design criteria related to EU “green” policies.

Further information

CLOSEWEE is a project funded by the European Union's Horizon 2020 (H2020) research and innovation programme.