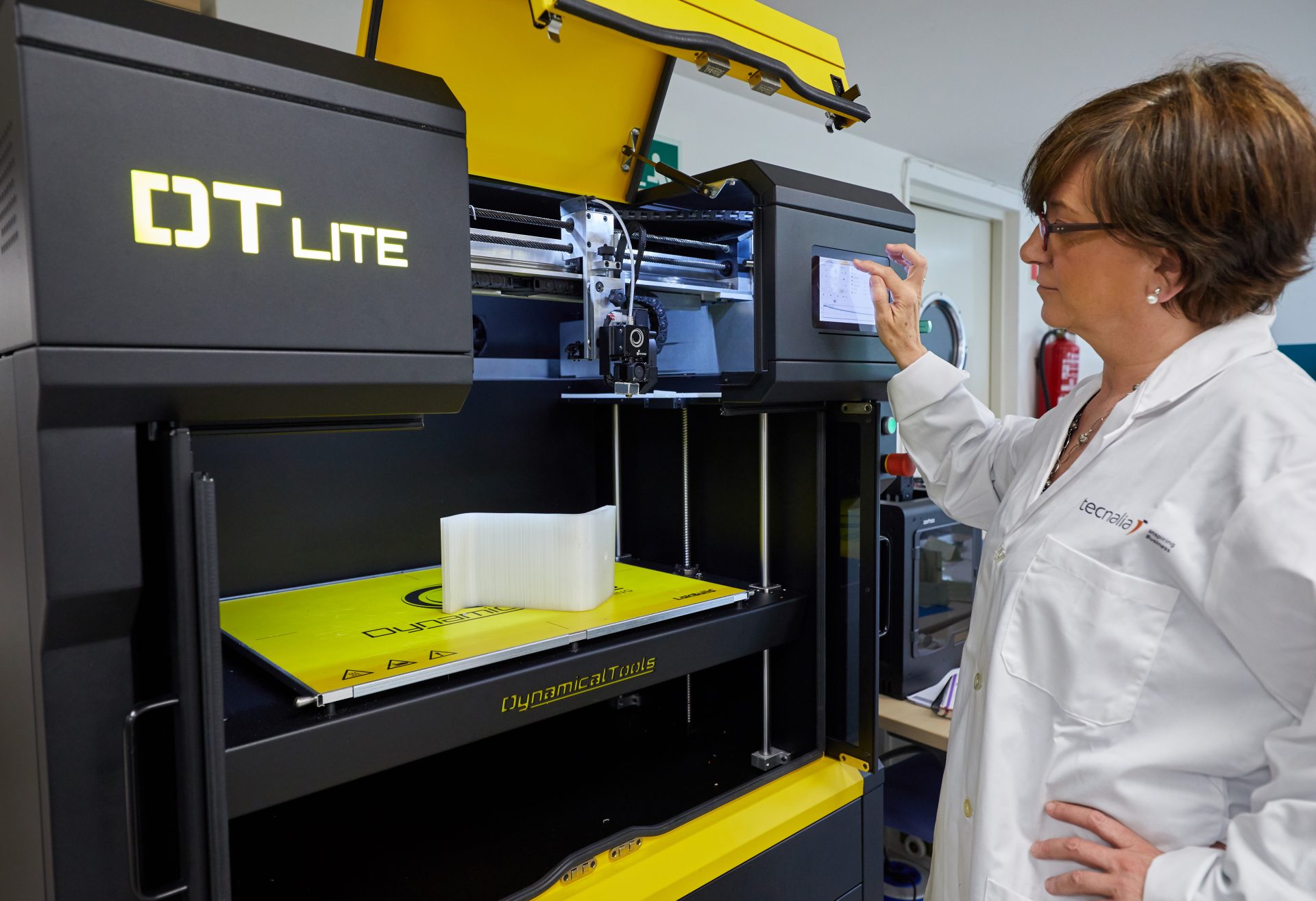

Laboratory that supports the development of additive manufacturing technologies for high performance plastics and composites, based on FDM (fused deposition modelling) – direct extrusion and hybridisation with liquid moulding processes.

Description

The laboratory has equipment for developing developing continuous fibre-reinforced polymeric composites and filaments, fine tuning manufacturing processes and impregnation and solidification post-processes.

It can also develop new design concepts to create moulds and tooling, final pieces, composite preforms, structural grids, 3D organosheets, and localised strengthening for integration in pre- or post-processes.

The main equipment the laboratory has includes:

- Material development unit: extruders for reformulating materials and filament extrusion.

- Injection machine and additive dispersion equipment (calender mill, Dispermart, ultrasonic baths and tips).

- Coating head using wire.

- Additive manufacturing unit: ZORTRAX M200, DYNAMICAL TOOLS DT600 and EOS printers – SLS and 6D equipment.

- TFP (tailored fibre placement) equipment and stitching head for manufacturing preforms using TFP.

Aimed at:

- Manufacturers of products and components made of thermoset and thermoplastic composites.

Related Laboratory Services