“Video extensometry offers many advantages in the analysis of materials and their manufacturing processes”

Video extensometry offers many advantages in the analysis of materials and their manufacturing processes

Minimal changes in dimension can be determined with video extensometry, thus extending the field of study of mechanical behaviour of materials compared to traditional measuring systems. The ability to control test speed by means of the extensometer throughout the test allows the strain rates imposed by certain test standards to be strictly adhered to. It is able to collect so much data that it determines minimal changes in the deformation of materials, thus enabling studies that were unthinkable a few years ago.

Other families of materials on which the laboratory is carrying out more and more tests are elastomers and plastics. The video extensometer has a high level of resolution and accuracy for working as per specifications set forth in ISO 527 and ASTM D638. It can also measure elongations prior to breakage, large elongations and elongations at breakage in samples where it is not possible to measure elongation after breakage (thin cables, wires, etc.).

Its ability to characterise and certify parts obtained using additive manufacturing is also a very interesting feature. Mechanical tests on "mini-test specimens” can also be controlled with the video extensometer. This works for both the manufacture of test specimens specifically for mechanical testing, where significant amount of material is saved, and for test specimens taken directly from the part or manufactured in a size that is similar to the critical dimensions to be assessed. This minimises the risk of the test specimen structure not exactly matching that of the component to be analysed.

Advanced lines of research in the field of materials, components and manufacturing processes

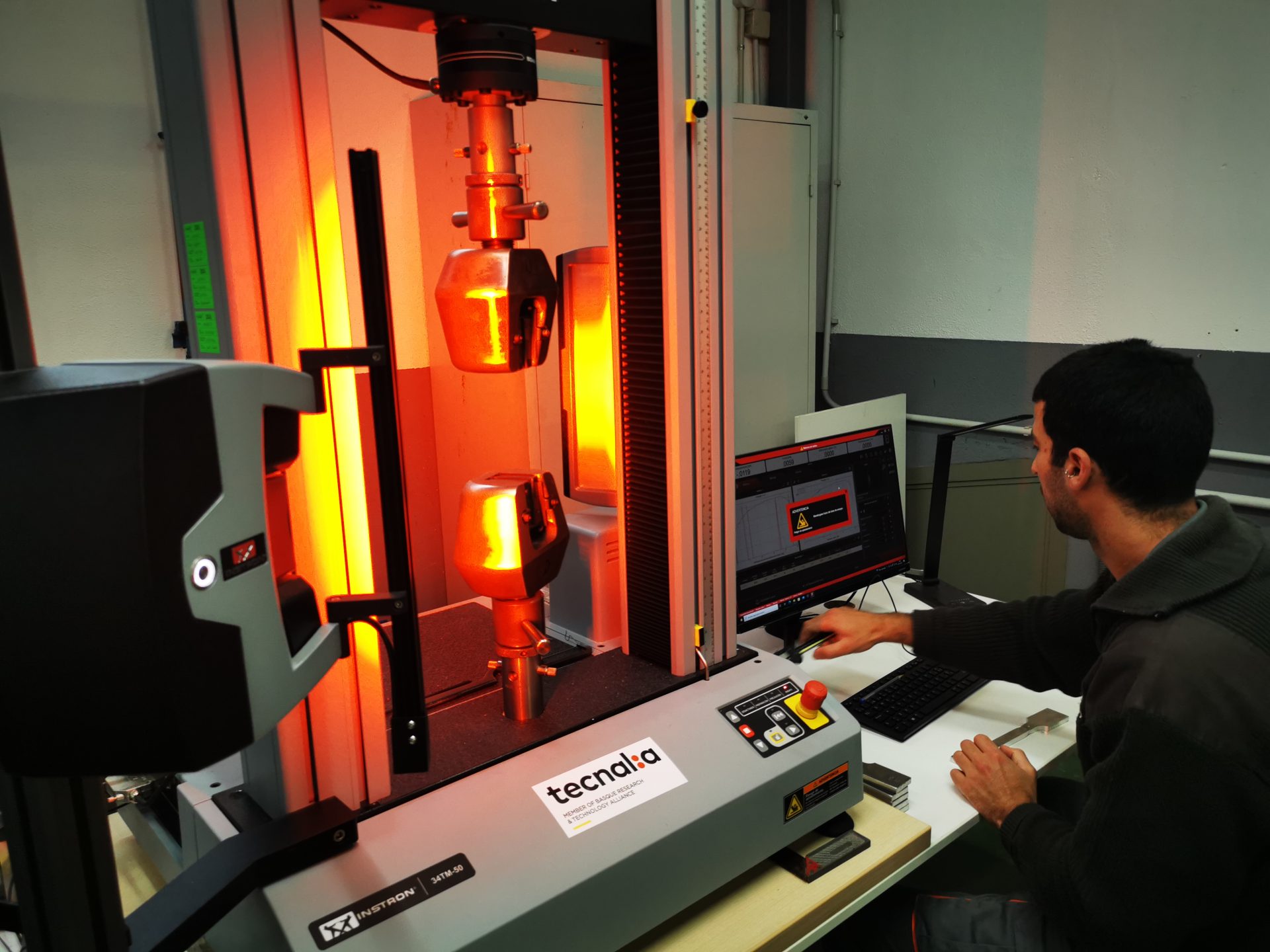

In TECNALIA’s Mechanical Testing Laboratory, as well as other means, there is a state-of-the-art video extensometer which enables accurate studies, such as strain-controlled fatigue tests, crack growth and fracture mechanics tests for various sectors such as aerospace, as well as the characterisation of biomaterials and implants for the healthcare sector, the measurement of transverse strain to obtain properties such as necking or Poisson's ratio, and sheet drawability parameters.