Laboratory for developing and characterising advanced membranes for producing hydrogen, separating gases and other compounds of industrial relevance.

These compounds can be used to capture CO2 in pre- and post-combustion, natural gas purification, O2/N2 separation and hydrocarbon separation processes, and processes that separate water from different products.

Description

This laboratory specialises in preparing and characterising membranes of different types and features the following equipment:

- System for manufacturing polymeric flat sheet and mixed matrix membranes.

- Spinning equipment for preparing single or double layer polymeric and mixed matrix hollow fibres and inorganic hollow fibres.

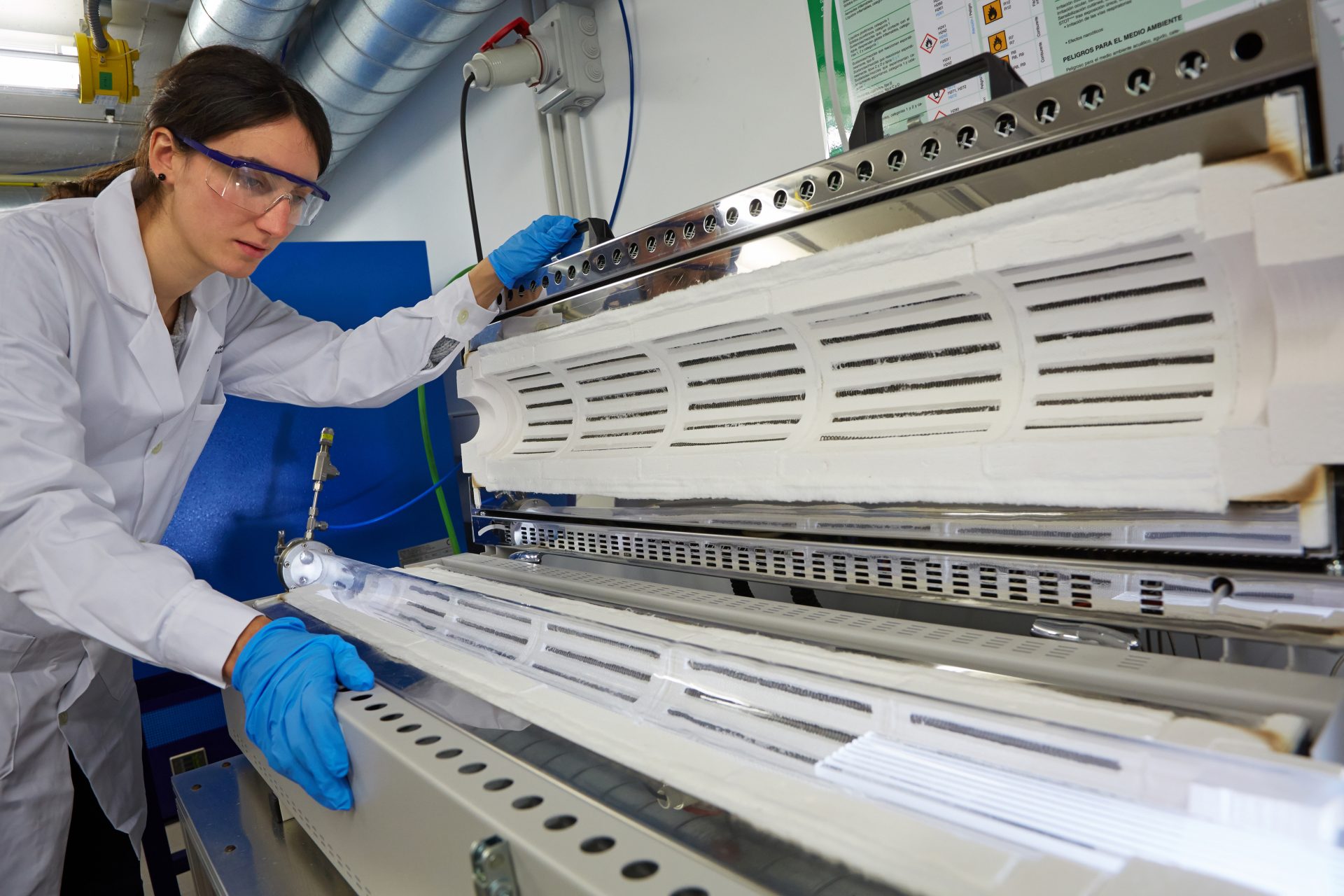

- Automated dip-coating equipment for preparing carbon-supported tubular membranes.

- Electroless plating and PVD equipment for preparing palladium-based thin-film membranes.

We also have low (RT-150ºC) and high (100-500ºC) temperature permeation equipment to determine the separation properties of the membranes, both for pure gases and for gas mixtures at different pressures (up to 100 bar).

The infrastructure also includes microstructural and chromatographic characterisation techniques.

This laboratory supports the preparation and characterisation of different types of membrane materials, such as:

- Polymeric membranes (hollow fibres).

- Inorganic membranes (e.g. Pd membranes and Pd base alloys, Pd “pore fill” membranes)

- Carbon molecular sieve membranes.

- Polymeric membranes with inorganic particles (mixed matrix hollow fibre membranes.

Aimed at:

Any industry involved in producing and separating gases.