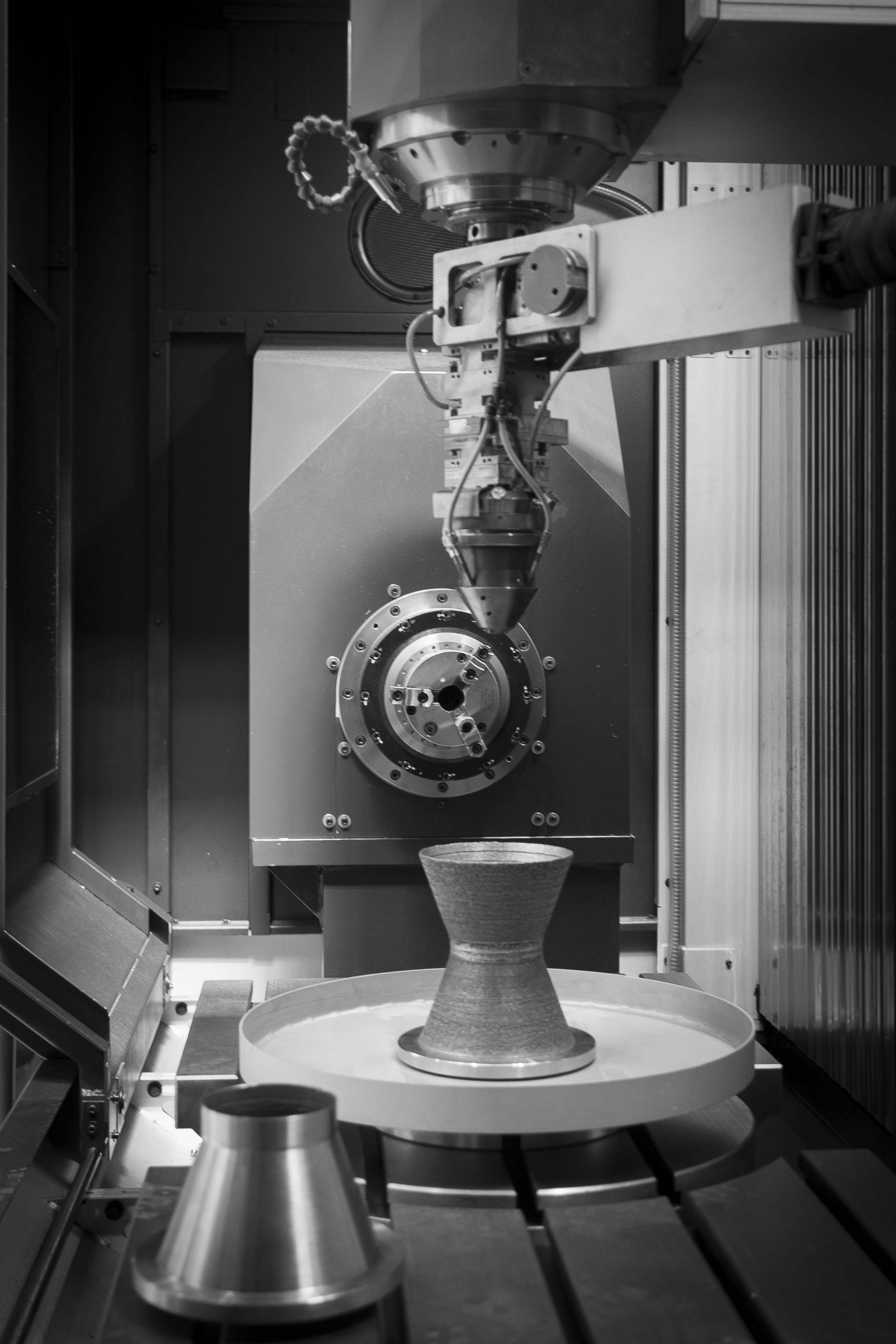

High productivity 5-axis machining centre, with fixed table and floor type architecture, capable of executing turning processes with horizontal and vertical plates, 5-axis machining and additive manufacturing by means of LMD-powder.

Description

The characteristics of the high productivity 5-axis machining centre with fixed table and floor type architecture are:

- Capacity to execute turning processes with horizontal (turning ø = 750 mm) and vertical (turning ø = 1,100 mm) plates.

- 5-axis machining with A+B and B+C.

- Additive manufacturing by means of LMD-powder, with X/Y/Z and B ravel of 1,600/800/900,mm and ±105º (±45º in LMD).

- Ability to program tool paths and simulation in PowerMill commercial CAM.

The cell components are:

- FL030 MM(FFC/FFS) 3 kW fibre laser source

- Lotec cooling.

- Rofin YC52 4-way or continuous LMD head

- Structured light technology for measuring parts.

- Sulzer Metco TWIN-10-C powder feeder.

- OPTRIS thermal imaging camera for monitoring molten baths (temperature range: 1000 – 2000 ºC).

- IDM sensor for controlling height.

Aimed at:

- Metalworking sector.

- Product developers, manufacturers of machinery, equipment and components

- Industrial service providers (control, programming/software, design, simulation and calculation)

- End users.