The nano cement laboratory develops technology for cement and derived products with lower CO2 emissions thanks to a lower consumption of natural resources and energy, with improved performance and new functionalities, such as energy storage, sensory systems, electric conductivity and superinsulation

Location

Description

The nano cement laboratory has human and technical resources for developing:

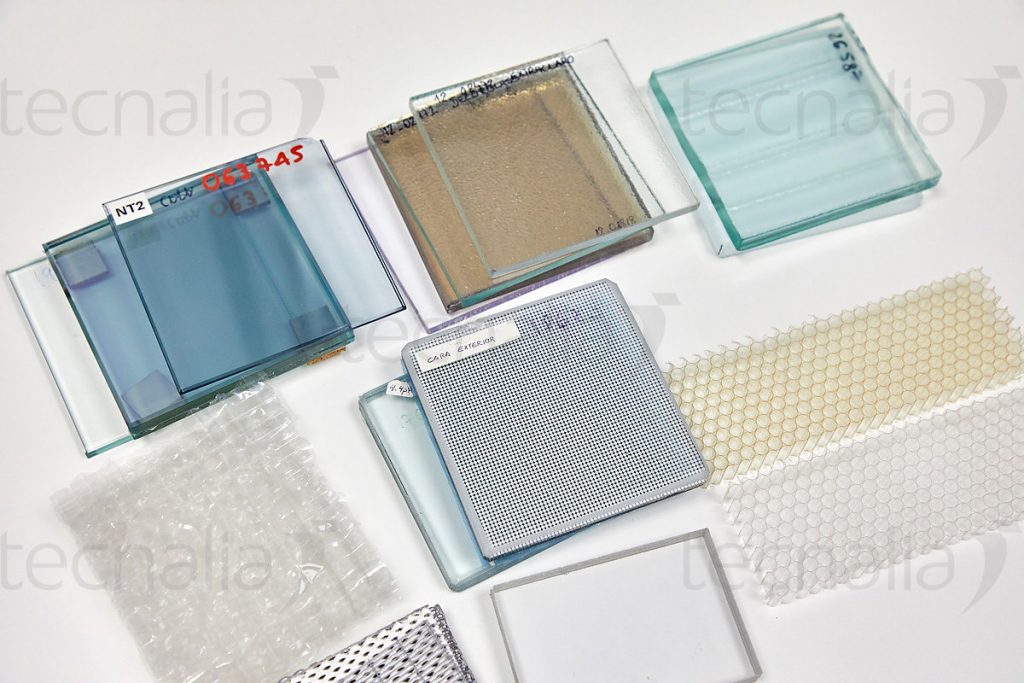

- Eco-cement and eco-concrete.

- Nanoadditions and additives.

- Nanostructured aerogels.

- Multifunctional construction materials..

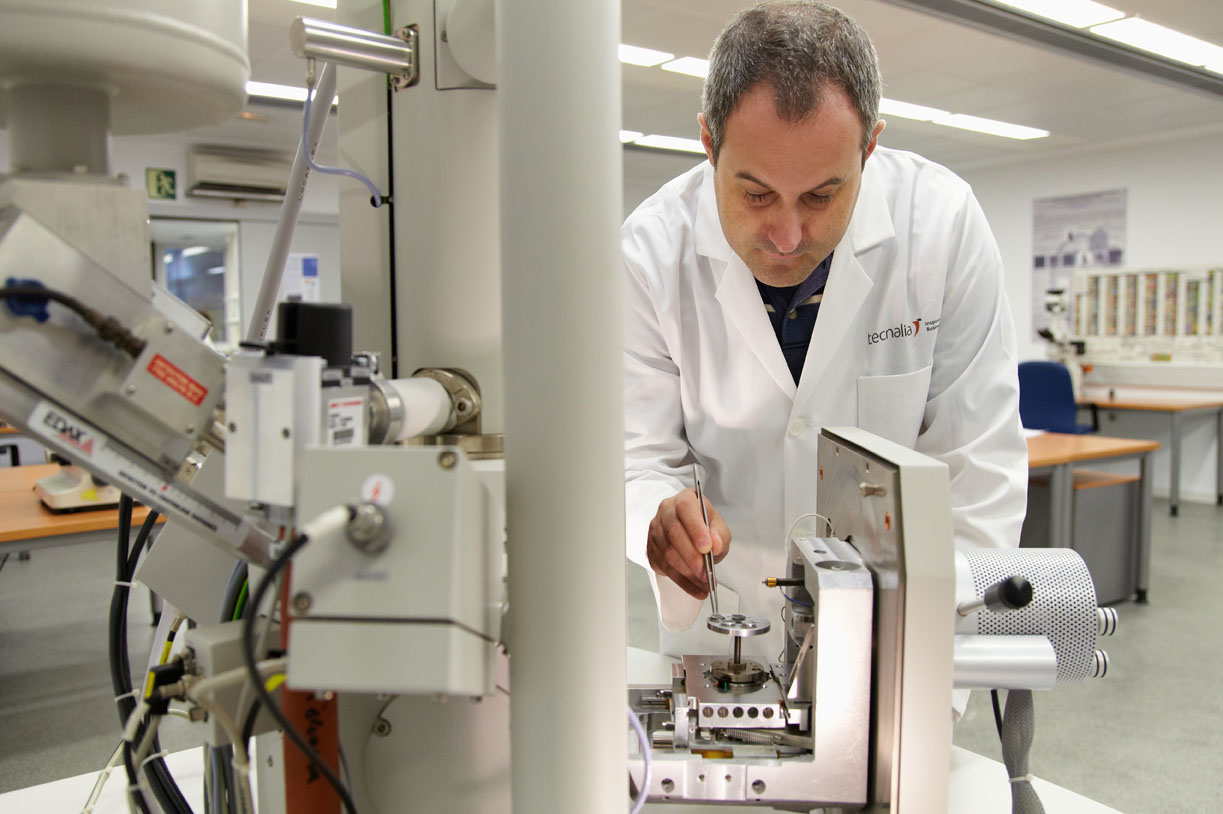

Most important equipment:

- Inspection of materials: binocular magnifiers, transmitted and reflected light petrographic microscope, environmental scanning electron microscope, atomic force microscope.

- Analysis of materials: mercury porosimeter, AcoustoSizer, infrared (FRIR), X-ray diffractometer, thermal conductivity measuring device, calorimeter, colorimeter, QUV chamber, photocatalytic reactor for degradation of NOx.

- Synthesis and handling of materials: Sol-Gel facility, supercritical chemical reactor, hydrothermal reactors, muffle furnaces, ovens, precision scales, micromill, climatic chambers, laminar flow cabinet, fume hoods, ultrasonic bath, centrifuge, cutting machine, polishing machine, stirrers.

- Material characterisation: rheometer, Vicat needle, press for mechanical strength, equipment for measuring linear shrinkage of mortar and concrete.

- Computational instrument for designing and forecasting: ab-initio, molecular dynamics and Brownian, Monte Carlo clustering…

Aimed at:

- Cement plants

- Concrete manufacturers

- Pre-cast Concrete

- Mortar manufacturers

Related Laboratory Services

Recognition

Recognised by TECNALIA as an International Excellence Group (GEI) - Green Concrete

Recognised as an asset of the Basque Innovation Hub: "Synthesis of nanomaterials and nanoparticles, advanced materials characterisation laboratory"

We are members of the Baskrete initiative, alongside DIPC, MPC, Polymat and UPV/EHU, which aspires to become the Green Concrete Cross-Border Joint Laboratory (LTC). This laboratory would be integrated by DIPC, MPC, Polymat, UPV/EHU, the University of Bordeaux, CNRS, and CSIC